- Home

- >

News

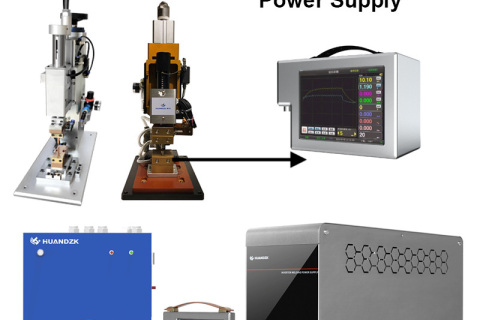

Four core technologies—resistance welding power supplies, hot press welding, welding monitors, and spot welding machines—underscore their critical role in modern intelligent manufacturing. Through high-precision control, real-time monitoring, and intelligent integration, these devices collectively ensure welding quality and improve production efficiency. Widely used in the automotive, electronics, and new energy sectors, they help companies achieve efficient, reliable, and defect-free welding processes.

The IDP welding source sets new standards in the field of precision welding power supply. With advanced digital control and seamless servo head integration, it delivers higher accuracy and efficiency than miyachi, bosch, or any inverter welding power supply manufacturer. Designed for demanding industries, the IDP system offers reliability, data traceability, and cost-effective welding solutions.

Huandian brought energy storage welding power supplies, pulse hot pressing welding, and welding monitors to the Essen exhibition, showcasing efficient and stable intelligent welding solutions to help upgrade the quality of industries such as automobiles, new energy, and electronics.

As a leading welding power supply company in Huizhou, we serve global automakers and battery manufacturers with cutting-edge technologies such as high-frequency inverters. We also offer free trial welding and invite you to collaborate during the September purchasing season!

At Canton Fair 2025, discover Chinese-made resistance welding power supplies, welding monitors, precision spot welders, transformers, and controllers. These solutions rival Miyachi and Bosch in quality—featuring closed-loop control and real-time monitoring—but at competitive local prices. Ideal for global manufacturers seeking advanced, cost-effective welding technology. Visit from Oct 15-19 in Guangzhou.

The IDP-Pulse pulse heating welding machine features precise multi-stage pulse temperature control, ultra-thin welding without heat loss, intelligent closed-loop monitoring, and compatibility with automated production lines, efficiently enabling precision manufacturing!

This spot welder is equipped with a high-precision IDP-8210 precision resistance welding power supply, which has the function of accurately judging welding quality. It supports multi-stage discharge and slow rise and fall, effectively avoiding current shock and ensuring stable and consistent welding. It supports host computer group control to achieve centralized management of multiple machines.

Capacitor energy storage spot welders have rapid discharge and minimal thermal impact, making them suitable for high-precision welding applications. Compatible with medium-frequency resistance welders, welding inverters, and welding analyzers, they are an ideal upgrade solution for high-frequency spot welders.

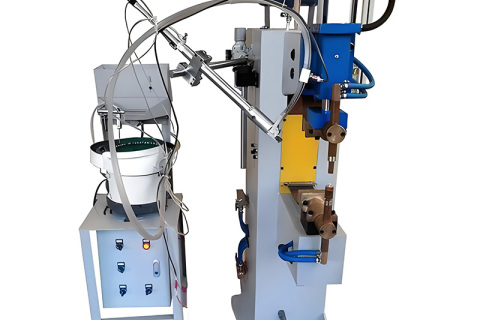

The nut automatic feeding welding machine combined with the IDW-200 anti-reverse detector realizes efficient, accurate and intelligent nut welding. It is widely used in industries such as automobiles, home appliances, and electronic equipment, significantly improving production efficiency and product quality.

Huandian IDP-620 and IDP-820 automotive spot welding inverter welding power supply welding equipment feature high-precision control, multi-stage discharge, intelligent judgment and rich interfaces, leading the industry standards and are ideal for automotive high-strength steel welding and intelligent production lines.

Urwelder is a high-tech enterprise specializing in the R&D and manufacturing of resistance welding systems. With a strong technical team and fully independent intellectual property, we offer a full range of advanced products including welding controllers, power supplies, and precision spot welders. Our solutions compete with top global brands and are trusted by high-end clients worldwide.

The HD-400B welding monitor has multi-parameter real-time monitoring, abnormal alarm, and quality judgment functions. HD-400B welding traceability system is compatible with a variety of spot welding models and is a key device for realizing intelligent welding and quality traceability.