- Home

- >

News

Our welding technology focuses on core areas of automotive manufacturing, providing professional resistance welding and spot welding solutions. Our products cover fuel tank sealing welding, high-strength spot welding for door frames and body structures, and high-precision, high-safety spot welding of electric vehicle battery modules and battery tabs.

Discover professional automotive welding solutions featuring a pro spot welder for sale, micro spot welder, robotic spot welding, and 3 phase spot welder technologies. Powered by an automotive welding power supply with monitoring system, these solutions deliver precision, stability, real-time quality monitoring, and high-efficiency production for modern automotive manufacturing.

Automotive resistance welding, including spot, projection, and seam techniques, is vital for assembling durable car bodies and components. These methods ensure precision, speed, and leak-proof bonds, supporting safety and efficiency in modern vehicle manufacturing, especially for EVs.

This article explores how a modern resistance spot welding machine monitor enhances real-time control, welding quality assurance, and data-driven optimization. By integrating current, voltage and displacement sensing with intelligent algorithms, manufacturers gain stable, consistent, and traceable results. High-value industries rely on precise monitoring to guarantee every weld meets strict production and reliability standards.

Welding professionals understand that transformer selection is critical for precision and efficiency. Our expert-approved range includes inverter welding transformers, high frequency welding transformers, resistance welding transformers, spot welding transformers, and multi-purpose welding machine transformers. Each unit delivers stable output, minimal spatter, and reliable operation, helping engineers and manufacturers achieve superior weld quality and consistent productivity.

Achieve precision, speed, and efficiency in welding with state-of-the-art transformers. Our range includes inverter welding transformers, high frequency welding transformers, resistance welding transformers, spot welding transformers, and versatile welding machine transformers. Designed for stability and consistent output, these transformers help manufacturers optimize performance, reduce defects, and improve productivity in every welding operation.

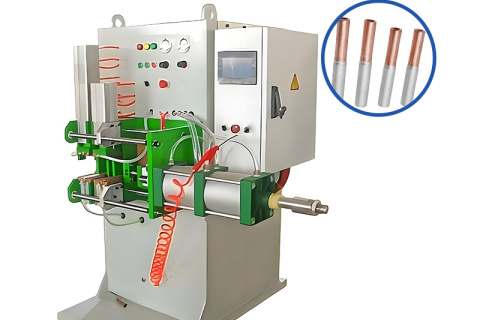

A roller spot welder and roll welding machine deliver stable, precise roll seam welding for metal fabrication. Many buyers compare roll spot welding machine price to select the most efficient roll spot welder. With continuous seam quality and strong welding performance, these machines improve productivity and guarantee reliable welding results.

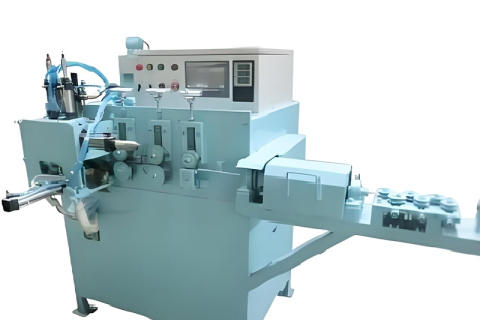

A multi-point spot welding machine boosts efficiency by welding multiple points at once. Paired with spot weld testing equipment, it ensures joint reliability. 3-phase welding machines deliver stable high-power output for industrial use. Hot bar welding machines enable precise, lead-free bonding of delicate components. Welding gun machines offer flexibility and easy automation integration—ideal for modern, high-precision manufacturing across automotive, electronics, and more.

Professional welding power supply manufacturer providing hot bar soldering machine, resistance spot welding machines, and precision resistance welding solutions worldwide.

Our welding solutions include the resistance roll welding machine, resistance bumper welding machine, and industrial pneumatic spot welding machine, powered by advanced welding machine power supply systems. These machines ensure precision, strength, and efficiency, serving automotive, electronics, and industrial sectors with reliable weld quality, productivity, and long-term performance.

Comprehensive resistance weld monitoring systems. Reliable resistance welding power supply technology. Durable butt resistance welding machine designs. Competitive china made spot welding machine solutions.