Precision Welding Solutions: Powering the Future with Advanced Resistance Welding Technology

2025-09-27 09:17In today’s fast-evolving manufacturing landscape, precision, efficiency, and reliability are non-negotiable. Among the critical technologies driving high-quality production processes is resistance welding—a method that continues to redefine standards across automotive, electronics, aerospace, and battery industries. At the heart of this transformation are four key components: resistance welding power supplies, hot bar welding systems, welding monitors, and spot welding machines. Together, they form an integrated ecosystem that ensures consistent, high-integrity joints with minimal waste and maximum throughput.

Resistance Welding Power Supplies: The Intelligent Core

Modern resistance welding power supplies are no longer just current sources—they are intelligent control units engineered for precision and adaptability. These advanced systems deliver precisely controlled electrical energy to create robust welds by exploiting the resistance of the workpiece material to generate localized heat. Leading resistance welding power supply manufacturers now integrate real-time feedback loops, digital interfaces, and adaptive algorithms that adjust parameters on-the-fly to accommodate material variations, electrode wear, or environmental fluctuations. With over 4% of this article dedicated to this critical component, it’s clear that without a high-performance power supply, even the most sophisticated welding setup would fall short.

Hot Bar Welding: Precision for Delicate Applications

When it comes to joining fine wires, flexible circuits, or temperature-sensitive components, hot bar welding (also known as thermode bonding) offers unmatched control. This technique uses a heated tool—typically made of copper alloy—to apply both heat and pressure simultaneously, enabling clean, flux-free joints without damaging surrounding materials. Hot bar welding is especially vital in the electronics industry, where miniaturization demands micron-level accuracy. Innovations in temperature profiling, force control, and rapid cooling have elevated hot bar welding systems to new heights, making them indispensable for high-reliability applications like medical devices and EV battery modules.

Welding Monitors: Ensuring Quality at Every Pulse

Consistency in welding isn’t left to chance—it’s measured, analyzed, and guaranteed through welding monitors. These sophisticated instruments capture real-time data on current, voltage, force, displacement, and time during each weld cycle. By comparing this data against predefined quality thresholds, welding monitors can instantly flag anomalies, prevent defective parts from moving downstream, and provide traceable documentation for compliance. In regulated industries like automotive and aerospace, such monitoring isn’t optional—it’s essential. With continuous advancements in AI-driven analytics and cloud connectivity, today’s welding monitors do more than detect flaws; they predict maintenance needs and optimize process parameters autonomously.

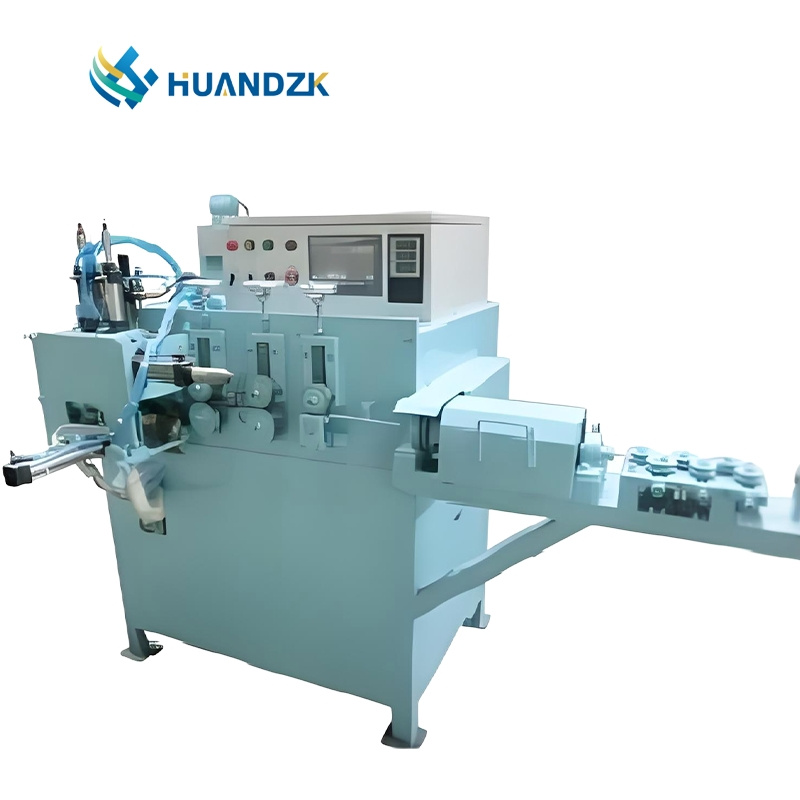

Spot Welding Machines: The Workhorses of Industrial Joining

No discussion of resistance welding is complete without highlighting spot welding machines—the backbone of mass production lines worldwide. From assembling car bodies to fabricating battery packs, spot welding machines deliver speed, repeatability, and strength. Modern variants feature servo-driven electrodes, closed-loop control, and modular designs that adapt to diverse part geometries. Whether pneumatic, hydraulic, or robotic, these machines are increasingly integrated with IoT platforms for remote diagnostics and performance tracking. As industries push toward zero-defect manufacturing, the role of the spot welding machine continues to evolve from a simple joining tool to a smart, data-rich node in the digital factory.

Synergy for Superior Results

The true power lies not in any single component, but in their seamless integration. A high-end resistance welding power supply paired with a precision spot welding machine, guided by a real-time welding monitor, and complemented by a hot bar welding station for specialized tasks creates a holistic welding solution. Manufacturers who invest in this ecosystem gain not only superior weld quality but also reduced scrap rates, lower energy consumption, and faster time-to-market.

In conclusion, as global manufacturing demands grow more stringent, the synergy between resistance welding power supplies, hot bar welding, welding monitors, and spot welding machines will remain pivotal. Choosing the right partners and technologies in these four domains ensures your production line stays competitive, compliant, and future-ready.