- Home

- >

News

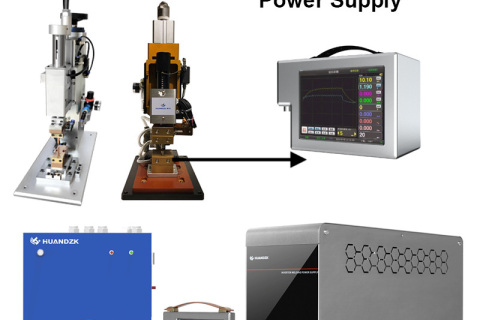

Four core technologies—resistance welding power supplies, hot press welding, welding monitors, and spot welding machines—underscore their critical role in modern intelligent manufacturing. Through high-precision control, real-time monitoring, and intelligent integration, these devices collectively ensure welding quality and improve production efficiency. Widely used in the automotive, electronics, and new energy sectors, they help companies achieve efficient, reliable, and defect-free welding processes.

Huandzk/Urwelder's IDP system welding power supplies and IDP resistance spot welders, combined with spot weld testing equipments, leverage the technological advantages of the welding power supply manufacturer to deliver efficient, accurate, and traceable welding solutions, empowering smart manufacturing.

The IDP welding source sets new standards in the field of precision welding power supply. With advanced digital control and seamless servo head integration, it delivers higher accuracy and efficiency than miyachi, bosch, or any inverter welding power supply manufacturer. Designed for demanding industries, the IDP system offers reliability, data traceability, and cost-effective welding solutions.

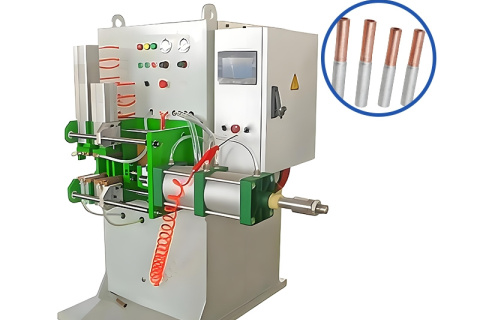

2025’s top stainless welding tech: best welder for stainless steel, automatic roll welding machine, roll spot and seam welding, fusion welding machine, resistance weld monitoring — boost precision, speed & smart control.

The five core elements of 2025 stainless steel welding: optimized welding machine, automatic roll welding, roller spot welding, fusion technology, and resistance welding monitoring, comprehensively improve efficiency, precision, and intelligence, and help upgrade high-end manufacturing.

The Resistance welding machine, Pulse Thermocompression Welding, Pulse Heat (Hot Bar Reflow) Soldering Machine, Pulse Heat Bonding, and Hot Bar Welding, highlighting their applications, advantages, and role in modern electronics and metal joining industries.

Huandian/Urwelder IDP precision welding power supply, with built-in monitor and high-precision control, is specially designed for intelligent automotive manufacturing. It shined at the Essen Exhibition in Germany, reshaping the new standard of intelligent welding with its self-developed "Chinese core".

Huandian brought energy storage welding power supplies, pulse hot pressing welding, and welding monitors to the Essen exhibition, showcasing efficient and stable intelligent welding solutions to help upgrade the quality of industries such as automobiles, new energy, and electronics.

There are obvious differences between the Huandian HD-400B and the Miyachi MM-400B in terms of functions, scenarios, cost-effectiveness and services. Huandian is more comprehensive and cost-effective, while Miyachi is suitable for special scenarios.

Urwelder and university doctors jointly developed the H-300 and H-500 pulse heating power supplies, integrating five-stage heating, full-process visualization, intelligent monitoring and MES interconnection to fully support high-end precision manufacturing.

At Canton Fair 2025, discover Chinese-made resistance welding power supplies, welding monitors, precision spot welders, transformers, and controllers. These solutions rival Miyachi and Bosch in quality—featuring closed-loop control and real-time monitoring—but at competitive local prices. Ideal for global manufacturers seeking advanced, cost-effective welding technology. Visit from Oct 15-19 in Guangzhou.

The IDP-Pulse pulse heating welding machine features precise multi-stage pulse temperature control, ultra-thin welding without heat loss, intelligent closed-loop monitoring, and compatibility with automated production lines, efficiently enabling precision manufacturing!