Transform Your Welding Projects with Next-Generation Welding Transformers

2025-11-19 17:40In modern manufacturing, achieving high-quality welds consistently is more critical than ever. The right welding transformer ensures your equipment delivers stable power, precise control, and reliable performance across various materials and welding methods. From automotive production lines to electronic component assembly, advanced transformers are the backbone of efficient welding processes.

Inverter Welding Transformers are among the most popular innovations in welding technology. These compact and energy-efficient devices use advanced electronics to regulate output current, offering precise arc control. Inverter welding transformers are ideal for both small-scale and industrial applications, providing clean, uniform welds with minimal spatter. Their lightweight design also makes them easier to integrate into automated welding systems, enhancing operational flexibility.

For tasks requiring ultra-stable power and fast response, High Frequency Welding Transformers offer significant advantages. Operating at higher frequencies, these transformers can provide reduced size, lighter weight, and improved energy efficiency. High frequency welding transformers are perfect for precision welding of thin metals, battery tabs, and intricate assemblies where accuracy is crucial. Their rapid response to load changes ensures consistent weld quality across high-volume production runs.

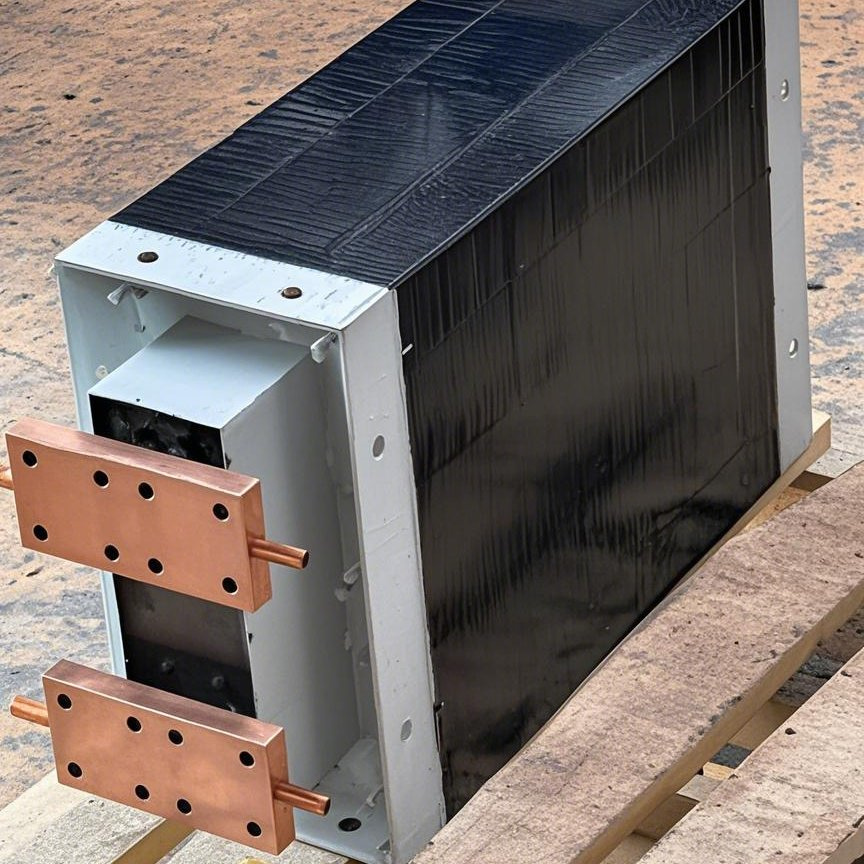

Resistance Welding Transformers are essential for heavy-duty applications that demand reliable, high-current power. By converting electricity into heat at the point of contact, these transformers enable strong and consistent welds in processes like spot welding, seam welding, and projection welding. Resistance welding transformers are widely used in automotive manufacturing, construction, and metal fabrication, ensuring durability and performance in repetitive welding operations.

Spot Welding Transformers specialize in delivering concentrated current bursts to precise points, ideal for thin sheets and delicate components. They produce high-quality, consistent welds while minimizing heat-affected zones. Spot welding transformers are commonly deployed in automotive body assembly, electronics, and battery manufacturing, where precision, speed, and repeatability are critical.

A versatile Welding Machine Transformer provides a comprehensive solution for multiple welding needs. These transformers can support AC, DC, inverter, and resistance welding processes, making them an indispensable asset in facilities with diverse production requirements. A high-quality welding machine transformer improves operational efficiency, reduces downtime, and ensures consistent results across various projects.

Selecting the right welding transformer involves evaluating output current capacity, input voltage compatibility, duty cycle, and cooling methods. Proper selection optimizes weld quality, minimizes defects, and improves energy efficiency. Additionally, modern transformers come with safety features such as thermal overload protection, robust insulation, and advanced cooling systems, guaranteeing durability and reliability in continuous industrial operations.

In conclusion, investing in advanced welding transformers is a smart decision for any manufacturer aiming for high-quality welds and efficient production. Whether you choose inverter welding transformers, high frequency welding transformers, resistance welding transformers, spot welding transformers, or versatile welding machine transformers, these tools provide the precision, consistency, and performance required for modern welding operations. Upgrade your welding setup today and experience the perfect combination of innovation, reliability, and productivity.