- Home

- >

- News

- >

- Company news

- >

News

Welding professionals understand that transformer selection is critical for precision and efficiency. Our expert-approved range includes inverter welding transformers, high frequency welding transformers, resistance welding transformers, spot welding transformers, and multi-purpose welding machine transformers. Each unit delivers stable output, minimal spatter, and reliable operation, helping engineers and manufacturers achieve superior weld quality and consistent productivity.

Achieve precision, speed, and efficiency in welding with state-of-the-art transformers. Our range includes inverter welding transformers, high frequency welding transformers, resistance welding transformers, spot welding transformers, and versatile welding machine transformers. Designed for stability and consistent output, these transformers help manufacturers optimize performance, reduce defects, and improve productivity in every welding operation.

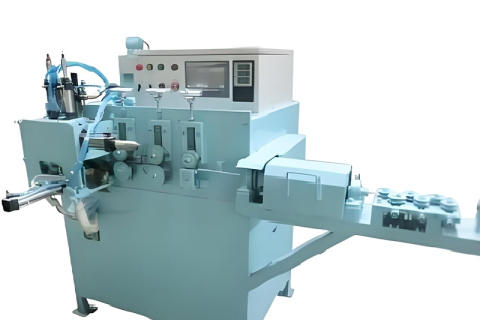

A high-performance roller welding machine, handwheel rolling and welding machine, and solutions from reliable seam welding machine manufacturers enhance modern metal processing. With specialized systems such as a copper wire seam welding machine and a metal box seam welding machine, factories achieve stable weld seams, improved efficiency, and consistent product quality across diverse industrial applications.

This article introduces advanced welding solutions including the automatic seam welding machine, automatic roll welding machine, horizontal seam welding machine, circular seam welding machine, and straight seam welding machine. These systems improve welding precision, boost productivity, and support automated manufacturing across industries such as automotive, HVAC, stainless-steel processing, and pressure vessel production.

This article highlights the advantages of seam welding machine technologies, including longitudinal seam welding machines, rolling welding machine systems, rolling spot welding machine equipment, seam welding machine longitudinal designs, and longitudinal welding machine automated welding machine solutions. These advanced machines improve welding accuracy, production efficiency, and long-term reliability across metal manufacturing industries.

Ensuring flawless weld quality is critical in modern manufacturing. With advanced welding monitors, welding checkers, and precise spot weld inspection systems, factories can achieve real-time welding quality control and accurate spot weld testing. These technologies guarantee strong, consistent joints, reduce production defects, and enhance overall efficiency and reliability in automotive, electronics, and metal fabrication industries.

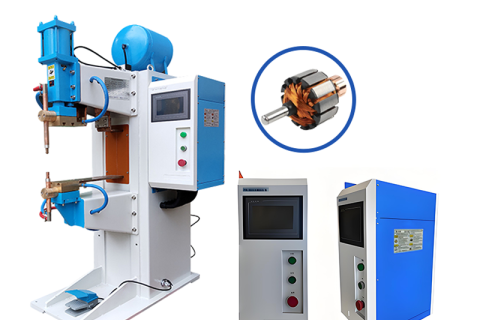

A multi-point spot welding machine boosts efficiency by welding multiple points at once. Paired with spot weld testing equipment, it ensures joint reliability. 3-phase welding machines deliver stable high-power output for industrial use. Hot bar welding machines enable precise, lead-free bonding of delicate components. Welding gun machines offer flexibility and easy automation integration—ideal for modern, high-precision manufacturing across automotive, electronics, and more.

The Huandian HD-400B Welding Monitor delivers real-time precision and reliability for advanced resistance welding. Featuring 20 kHz high-speed sampling, waveform recording, and intelligent data analysis, it ensures consistent weld quality and full traceability. Ideal for automotive, electronics, and battery manufacturing, it’s the ultimate solution for modern welding quality control.

At the Canton Fair 2025, China’s leading welding power supply manufacturer will exhibit advanced Pulse Hot Press Welding systems, Resistance Spot Welders, and Welding Monitoring Instruments. With self-developed control and precision technology, the company brings smart, efficient welding solutions for global electronics, automotive, and new energy industries.

At the 2025 Canton Fair (Oct 15–19, Guangzhou), China’s largest resistance welding power supply manufacturer presents its latest IDP series welding power supplies, welding monitors, pulse heat welding, and capacitor discharge welding systems—showcasing precision control, intelligent monitoring, and advanced welding technology for global industries including electronics, automotive, and energy applications.

Explore the latest pedal pair welding machines and welding transformer manufacturers at the Canton Fair, featuring high-efficiency welding equipment for resistance welding that delivers precision, durability, and intelligent control for modern industrial applications.

Comprehensive resistance weld monitoring systems. Reliable resistance welding power supply technology. Durable butt resistance welding machine designs. Competitive china made spot welding machine solutions.