- Home

- >

News

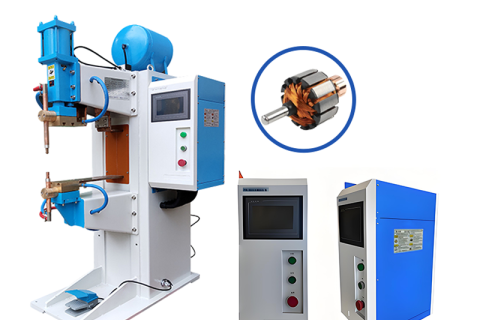

380V copper wire welding machine is known for its high efficiency and reliability, and is widely used in the fields of electronics and electrical appliances. Its high-precision welding technology ensures quality and is suitable for copper wires of multiple specifications. When choosing, you need to consider power, technical parameters and brand quality. Huandian IDP series inverter DC welding power supply uses imported components and advanced technology to provide precise control and low-damage welding, helping enterprises to produce efficiently.

Elevate your welding operations with state-of-the-art transformers designed for precision and efficiency. Our range includes frequency conversion welding transformers, variable frequency welding transformers, frequency inverter welding transformers, variable frequency spot welder transformers, and IGBT inverter welding transformers. Experience stable arcs, minimal spatter, and consistent output—perfect for high-performance industrial welding and advanced manufacturing processes.

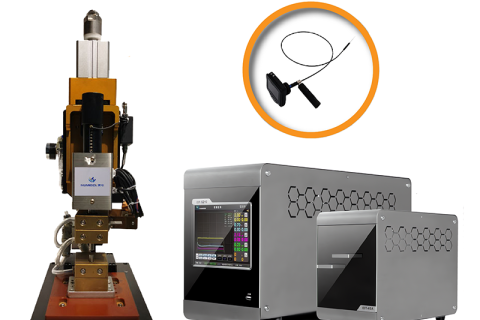

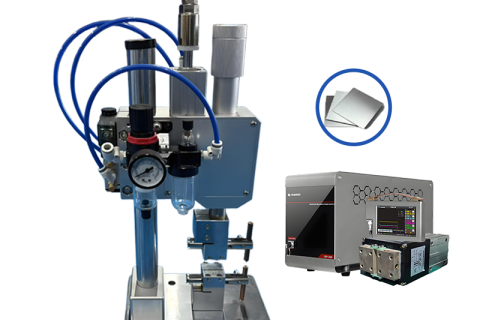

This article examines the role of the high-precision welding DC power supply in advanced micro-joining applications. It details how the DC precision welding transformer and precision DC welding system improve weld quality, minimize spatter, and maintain stable current. The discussion highlights why industries increasingly rely on the direct current welding power unit to achieve consistent and reliable performance.

Welding professionals understand that transformer selection is critical for precision and efficiency. Our expert-approved range includes inverter welding transformers, high frequency welding transformers, resistance welding transformers, spot welding transformers, and multi-purpose welding machine transformers. Each unit delivers stable output, minimal spatter, and reliable operation, helping engineers and manufacturers achieve superior weld quality and consistent productivity.

Achieve precision, speed, and efficiency in welding with state-of-the-art transformers. Our range includes inverter welding transformers, high frequency welding transformers, resistance welding transformers, spot welding transformers, and versatile welding machine transformers. Designed for stability and consistent output, these transformers help manufacturers optimize performance, reduce defects, and improve productivity in every welding operation.

Explore the latest pedal pair welding machines and welding transformer manufacturers at the Canton Fair, featuring high-efficiency welding equipment for resistance welding that delivers precision, durability, and intelligent control for modern industrial applications.

At Canton Fair (Oct 15-19), discover Chinese-made resistance welding power supplies, welding monitors, precision spot welders, transformers, and controllers. These offer Miyachi/Bosch-level quality at localized prices, ideal for cost-effective, high-performance manufacturing. Visit us for advanced solutions.

As a leading company in the field of domestic welding power sources, Ur Welder provides customized technical training and process optimization support to customers in Indonesia and neighboring countries through its localized service network in Southeast Asia, helping the manufacturing industry to upgrade to intelligence and greenness, and using innovative technologies to promote the global welding industry to a new stage of "precision, efficiency and sustainability".

The multi-point precision welding power supply has excellent functions, 6 control modes, 5 optional frequencies, supports multi-stage welding, has pressure triggering, etc., can weld efficiently and accurately, and ensure product quality.

We have been deeply engaged in the field of welding, constantly breaking through technical bottlenecks, and launching new products such as the IDP series welding power supplies, welding transformers, welding heads, monitors, etc., to achieve both performance and intelligence improvements, and comprehensively help welding applications in multiple industries reach new heights.

We will participate in the Hanoi Welding Exhibition in May 2025, Vietnam, to showcase advanced equipment such as DC and AC welding power supplies, welding transformers, resistance spot welders and welding monitors.