- Home

- >

News

Urwelder releases IDP series high-frequency inverter DC power supply, which adopts high-frequency inverter and DSP technology, 0.2 millisecond precision control, imported components to ensure stability, and is suitable for precision welding scenarios such as automobiles and 3C electronics, promoting intelligent and efficient production.

DC inverter transformers achieve DC voltage conversion by relying on technologies such as high-frequency chopping and transformer isolation. They have the advantages of high efficiency and high power density and are widely used in new energy, electric vehicles and other fields.

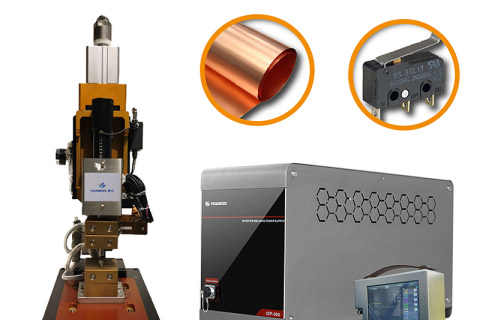

Precision seam welding spot welding machines and wire harness nickel sheet spot welding machines are suitable for welding a variety of metals. Resistance welding machines have the characteristics of high efficiency, energy saving, and easy operation. They are widely used in many fields such as automobiles, electronics, and batteries. They are the preferred equipment for efficient welding.

Due to their different frequency characteristics, medium-frequency DC inverter transformers and high-frequency DC inverter transformers are suitable for industrial heating, medical equipment, new energy, and communications fields, respectively78. This article analyzes the advantages and disadvantages of the two in terms of efficiency, anti-interference, load adaptability, and cost, and provides a technical basis for selection.

Medium frequency DC transformers are efficient, compact, low harmonic, and suitable for new energy, industry, and transportation. They empower the future of green energy with high-frequency devices and innovative control.

China's top welding power supply and spot welding machine manufacturer appeared at the Kielce Spring Industrial Exhibition in Poland, demonstrating its core technologies and intelligent solutions, which won praise from customers. On-site practical operations promoted transactions and exhibition expectations were achieved.

Resistance welding transformers have high welding efficiency, fast speed, strong weldment, and reduce welding costs. They are suitable for welding a variety of materials, such as aluminum alloys and aluminum and other materials with fast thermal conductivity and poor weldability. In addition, for the welding of galvanized sheets and ordinary multi-layer sheets, welding transformer's welding quality is also much higher than that of power frequency welding machines.

Lithium battery spot welding equipment has gone through many generations of development, each with its own characteristics. Huandian DC inverter precision power supply, with its excellent performance and stability, optimizes output, improves stability and efficiency, and meets various welding needs. Despite technological advances, different spot welding machines still have their own capabilities.

Ur welder provide high power high frequency DC welding power supplies, resistance spot welders, resistance weld monitorings, and professional customized automotive suspension spot welding solutions to ensure efficient and stable welding.

Precision resistance welding machines are widely used in the electronics, battery, automotive and medical industries. With high-precision welding power supplies, welding transformers and welding monitors, they can achieve efficient and stable welding and help upgrade smart manufacturing.

During the Spring Festival holiday from January 20 to February 5, 2025, we suspended production but the business team was on standby. The core products include welding power supplies and intelligent solutions, with innovative functions such as multi-stage welding and servo control.

We provide advanced welding solutions, including precision power supplies, spot welding power controller, spot welding machine transformer, and welding quality inspection device. Our products enhance welding quality, control, and efficiency, offering real-time monitoring, data analysis, and network integration for improved performance and traceability.