- Home

- >

News

High-efficiency welding inverter transformer technology combined with a stable spot welding power supply enhances MFDC spot welding machine automotive applications and roller spot welding machines. Integrated capacitor discharge welding monitors provide real-time quality control, consistent energy output, and improved welding reliability for demanding industrial and automotive production environments.

This overview introduces professional welding quality monitoring solutions, including nut welding monitoring system, seam welding quality control, capacitor discharge welding monitor, micro spot welding quality tester, and inverter resistance welder monitor. It highlights how real-time data acquisition, process monitoring, and traceability improve weld consistency, defect detection, and overall manufacturing reliability across industrial welding applications.

This article explores how a modern resistance spot welding machine monitor enhances real-time control, welding quality assurance, and data-driven optimization. By integrating current, voltage and displacement sensing with intelligent algorithms, manufacturers gain stable, consistent, and traceable results. High-value industries rely on precise monitoring to guarantee every weld meets strict production and reliability standards.

Ensuring flawless weld quality is critical in modern manufacturing. With advanced welding monitors, welding checkers, and precise spot weld inspection systems, factories can achieve real-time welding quality control and accurate spot weld testing. These technologies guarantee strong, consistent joints, reduce production defects, and enhance overall efficiency and reliability in automotive, electronics, and metal fabrication industries.

The Huandian HD-400B Welding Monitor delivers real-time precision and reliability for advanced resistance welding. Featuring 20 kHz high-speed sampling, waveform recording, and intelligent data analysis, it ensures consistent weld quality and full traceability. Ideal for automotive, electronics, and battery manufacturing, it’s the ultimate solution for modern welding quality control.

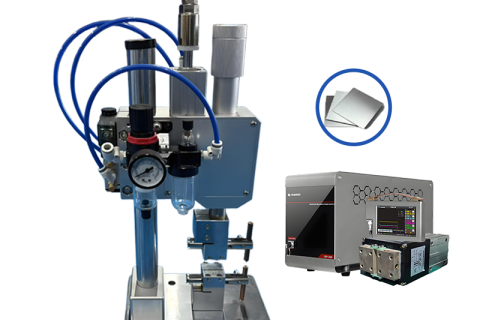

At the Canton Fair 2025, China’s leading welding power supply manufacturer will exhibit advanced Pulse Hot Press Welding systems, Resistance Spot Welders, and Welding Monitoring Instruments. With self-developed control and precision technology, the company brings smart, efficient welding solutions for global electronics, automotive, and new energy industries.

We specialize in pulse hot press welding, thermocompression welding machines, and hot bar welders with intelligent welding monitoring devices. Our systems ensure precise, reliable, and repeatable nickel strip welding for electronics, batteries, and precision assemblies, providing real-time quality monitoring, data traceability, and superior bonding performance. Trusted globally for efficiency and consistency.

At Canton Fair (Oct 15-19), discover Chinese-made resistance welding power supplies, welding monitors, precision spot welders, transformers, and controllers. These offer Miyachi/Bosch-level quality at localized prices, ideal for cost-effective, high-performance manufacturing. Visit us for advanced solutions.

Four core technologies—resistance welding power supplies, hot press welding, welding monitors, and spot welding machines—underscore their critical role in modern intelligent manufacturing. Through high-precision control, real-time monitoring, and intelligent integration, these devices collectively ensure welding quality and improve production efficiency. Widely used in the automotive, electronics, and new energy sectors, they help companies achieve efficient, reliable, and defect-free welding processes.

Huandian/Urwelder IDP precision welding power supply, with built-in monitor and high-precision control, is specially designed for intelligent automotive manufacturing. It shined at the Essen Exhibition in Germany, reshaping the new standard of intelligent welding with its self-developed "Chinese core".

There are obvious differences between the Huandian HD-400B and the Miyachi MM-400B in terms of functions, scenarios, cost-effectiveness and services. Huandian is more comprehensive and cost-effective, while Miyachi is suitable for special scenarios.

Ur Welder will bring high-end products such as welding transformers, controllers, and monitors to the Shanghai Automotive Welding Exhibition, with performance exceeding Miyachi, helping customers improve efficiency and welding quality.