- Home

- >

News

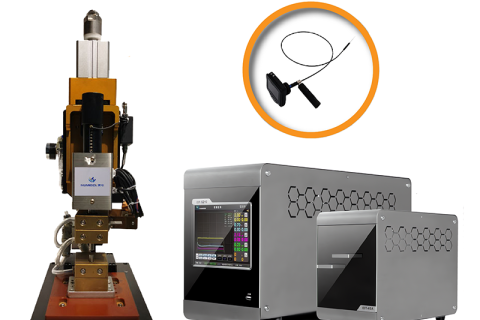

380V copper wire welding machine is known for its high efficiency and reliability, and is widely used in the fields of electronics and electrical appliances. Its high-precision welding technology ensures quality and is suitable for copper wires of multiple specifications. When choosing, you need to consider power, technical parameters and brand quality. Huandian IDP series inverter DC welding power supply uses imported components and advanced technology to provide precise control and low-damage welding, helping enterprises to produce efficiently.

Advanced solutions including high frequency pulse welder technology, PCB interconnect welding processes, heat pulse control system integration, spot welding copper to copper capability, and precision spot welding pneumatic controller design deliver stable energy control, consistent weld quality, and efficient production for modern electronics and high-conductivity metal joining applications.

Advanced manufacturing relies on the best capacitor discharge welder for battery tab welding, intelligent systems competing with Miyachi controllers, and integrated weld inspection instrument monitoring. From Automotive nut and bolt projection welding to precision work using a spot welding machine for stainless steel, these solutions ensure stable quality, efficiency, and automation readiness.

Precision manufacturing benefits from spot welding thermocouple wires, stable resistance welding machine price, and accurate inverter resistance welder monitor control. Using an automated pulse welder and understanding capacitor discharge welding process explanation ensures consistent, high-quality welds. This integrated approach boosts efficiency, repeatability, and reliability across modern industrial and automotive production lines.

An advanced Automotive projection welding machine combined with a smart welding quality control system ensures stable, traceable production. Precise control of spot welding machine voltage and current improves weld consistency. A flexible multi functional welding machine and high-performance welding roller machine together deliver efficient, reliable solutions for modern automotive manufacturing lines.

Searching for the best automotive resistance welding solution for EV motor stator resistance welding? As a China automotive welding machine manufacturer, we provide advanced automotive resistance welding technology and act as a trusted automotive spot welding equipment supplier for global EV production lines.

Urwelder delivers robotic resistance welding automation for automotive production, combining inverter resistance welding machine technology, stable welding resistance control, and efficient multi spot welding. Our metal welding machine solutions ensure high productivity, consistent weld quality, and reliable performance for modern automotive manufacturing lines.

High-efficiency welding inverter transformer technology combined with a stable spot welding power supply enhances MFDC spot welding machine automotive applications and roller spot welding machines. Integrated capacitor discharge welding monitors provide real-time quality control, consistent energy output, and improved welding reliability for demanding industrial and automotive production environments.

Advanced power supply for spot welding solutions support wire terminal resistance welding, micro spot welding machines, gun welding machines, and diffusion welding machines. Intelligent current control, fast response, and process stability ensure consistent weld quality, higher productivity, and reliable performance across electronics, automotive, and high-end manufacturing applications.

This integrated solution features a resistance welding analyzer, durable resistance welding electrodes, resistance welding press multifunctional, spot welding machine small, and long seam welding machine. It ensures precise weld monitoring, versatile production capabilities, and high-quality results for automotive, electrical, and industrial applications.

This overview introduces professional welding quality monitoring solutions, including nut welding monitoring system, seam welding quality control, capacitor discharge welding monitor, micro spot welding quality tester, and inverter resistance welder monitor. It highlights how real-time data acquisition, process monitoring, and traceability improve weld consistency, defect detection, and overall manufacturing reliability across industrial welding applications.