- Home

- >

News

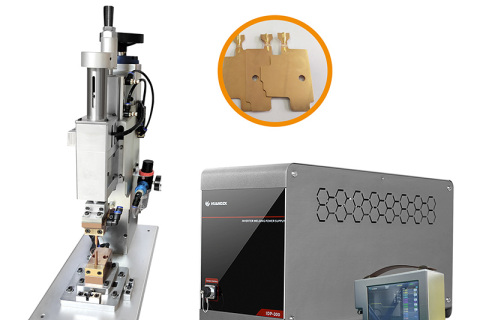

The precision spot welding machine adopts advanced inverter power supply, with stable heat output and fast response; the welding wire does not need to be processed and the operation is efficient; the welding wire diameter range is wide and applicable to many scenarios;

Precision DC spot welding machine, efficient and accurate, environmentally friendly and energy-saving. DC output, concentrated heating, good forming, traceless welding; high-precision control, fast response, high thermal efficiency; compact structure, easy operation, adaptable to a variety of environments, widely used in the field of precision welding.

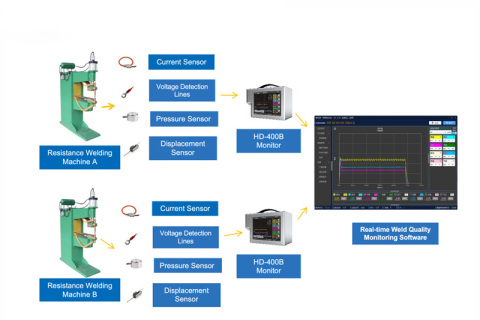

A magical tool for monitoring resistance welding machines, compatible with multiple types, capable of measuring current, voltage and power, alarming within seconds of exceeding the limit, storing millions of data, and keeping track of welding quality!

The precision resistance welding equipment integrates intelligent monitoring, real-time detection of current, voltage and other parameters, automatic alarm when exceeding the limit and rejection of defective products; built-in large-capacity database stores welding data and fault records, supports USB flash drive export and analysis; multi-stage welding is combined with slow rise and slow fall technology to effectively reduce spatter and improve welding stability.

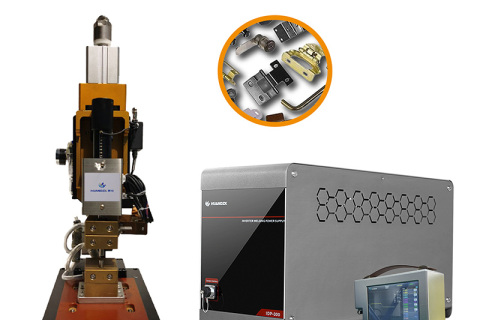

The precision welding spot welding machine adopts 0.2 millisecond high-precision control and servo pressure system, combined with mechanical positioning and electrical signal detection dual anti-reverse technology, to achieve low thermal damage and high stability in nut welding. The strength of the weld is more than 90% of the parent material, and the defective rate is less than 0.5%. It is widely used in high-precision manufacturing fields such as automobiles and electronics.

Precision spot welding machines are the "stars" of industrial manufacturing, specially customized for precision workpieces, and can finely control resistance welding parameters. Precision workpieces are used in many cutting-edge industries.

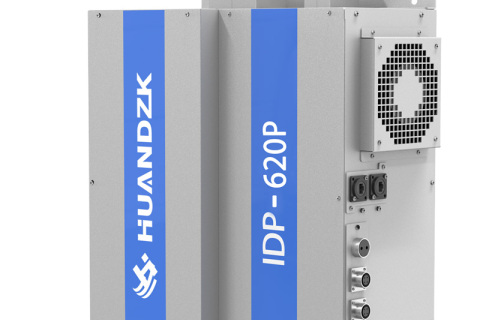

Precision inverter resistance welding provides solutions for metal contact welding, with many advantages, such as high efficiency and good solder joints. Precision inverter resistance welding power supply features include DC output, intelligent control, soft switching technology, etc. DC inverter resistance spot welding machine has fast response and high precision, and is very suitable for precision welding, with broad application prospects.

Huandian inverter precision welding controller has six control modes to accurately adapt to the needs, multiple working frequencies for flexible selection, servo motor voltage control and stable, clever combination of pulse discharge, excellent human-machine interface, complete monitoring functions, and convenient data storage, which can provide efficient and stable resistance welding throughout the process.

Automotive spot welders are widely used in automobile manufacturing for welding ignition coils, precision electronic components and car bodies. Although the resistance welding process has certain requirements on materials, it has high control accuracy and stable performance, which can ensure welding consistency and quality.

We focus on welding technology and intelligent solutions, provide hardware such as ultra precision welding power supplies and intelligent systems such as welding monitoring and networking group control, and will appear at the 20th Vietnam International Machinery Equipment and Industrial Technology Exhibition in 2024.

Spot welding machines are widely used welding tools, suitable for a variety of non-ferrous metals. The welding quality is affected by parameter adjustment, and attention should be paid to product thickness limitations and equipment maintenance.

The precision spot welding machine has good welding effect. When installing and using it, you need to pay attention to lead selection, safety protection, component tightening and oxide cleaning, ensure the normal voltage of the power grid, and pay attention to the maintenance of wearing parts.