- Home

- >

News

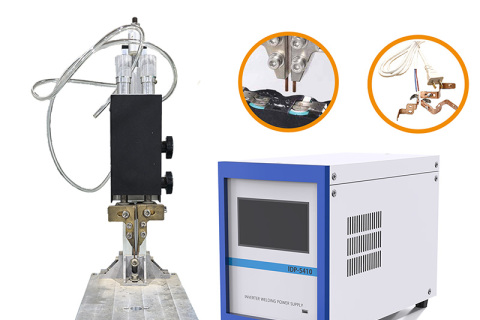

Servo clamp welding tandem spot welding machine has precise and controllable pressure, concentrated energy, less spatter, stable and reliable welding, and is suitable for high thermal conductivity materials such as copper and aluminum and precision welding applications.

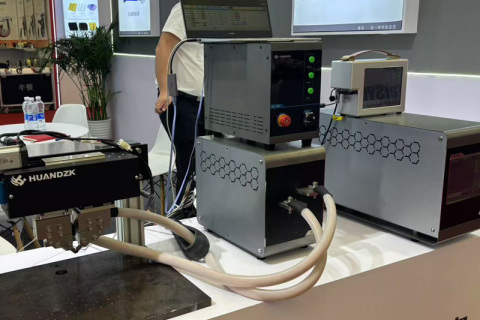

Huandian will appear at the 2025 Beijing Essen Welding Exhibition, displaying core products such as ultra-precision welding power supplies, high-frequency spot welders, and DC inverters, fully demonstrating its technological leadership in the field of resistance welding.

Precision resistance welding is widely used in the field of electric motors. It can accurately weld commutators and other components in rotor manufacturing, and ensure that windings and other components are firmly connected and of stable quality in stator production.

Urwelder Welding Technology Co., Ltd. will be present at the Hanoi Industrial Exhibition in Vietnam with its self-developed precision resistance welding power supply, all-round welding detector and other products, leveraging the traffic of 20,000 visitors to expand the international market and enhance brand and product awareness.

We will participate in the Hanoi Welding Exhibition in May 2025, Vietnam, to showcase advanced equipment such as DC and AC welding power supplies, welding transformers, resistance spot welders and welding monitors.

At booth 1A-A16 at the Polish Spring Industrial Exhibition, welding power supply manufacturers will showcase their cutting-edge welding technology matrix, with independent research and development, international quality, and intelligent monitoring to help reduce costs and increase efficiency.

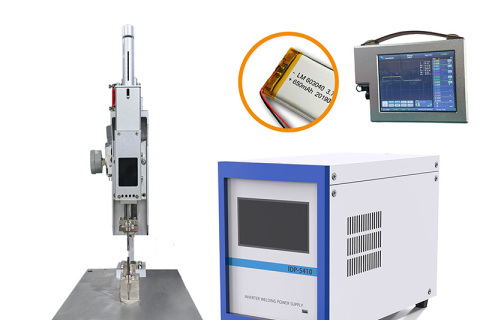

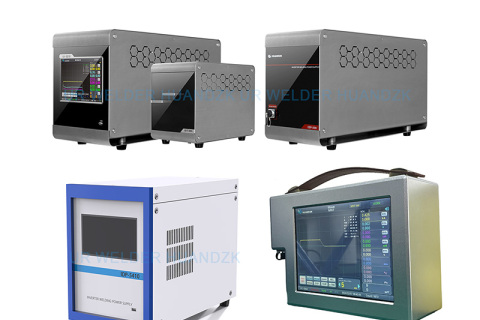

Huandian has launched a high-precision welding power source, which is specially designed for new energy battery manufacturing to improve welding efficiency and quality. It has been widely used in many fields and has begun to produce products in factories in Indonesia, India, Brazil, Turkey, the United States, Vietnam and other countries. The quality is comparable to that of Miyachi and Bosch, and it has won the trust and praise of domestic and foreign customers.

Huandian's latest developed welding power supply has achieved remarkable results in the field of new energy battery welding with its high efficiency, precision and stability, leading the industry's technological innovation and improving production efficiency and product quality.

When choosing a lithium battery spot welding machine welding power supply, you need to consider the welding effect, scope of application and cost. Capacitor energy storage, inverter and AC welding power supplies each have their own advantages, suitable for different scenarios and meet diverse needs.

Ur welder provide high power high frequency DC welding power supplies, resistance spot welders, resistance weld monitorings, and professional customized automotive suspension spot welding solutions to ensure efficient and stable welding.

We will showcase its advanced IDP series precision welding power supplies at the Poland International Welding Technology and Equipment Exhibition. With precise control, intelligent monitoring and innovative technology, it will promote the development of the welding industry and provide efficient and stable intelligent welding solutions.