- Home

- >

News

As a leading company in the field of domestic welding power sources, Ur Welder provides customized technical training and process optimization support to customers in Indonesia and neighboring countries through its localized service network in Southeast Asia, helping the manufacturing industry to upgrade to intelligence and greenness, and using innovative technologies to promote the global welding industry to a new stage of "precision, efficiency and sustainability".

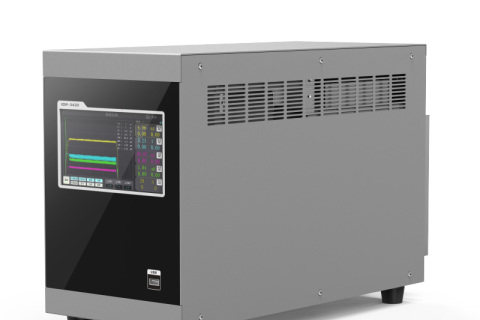

At the 25th Moscow International Metalworking Exhibition, the independently developed IDP series high-frequency inverter DC welding power source stood out with its high control accuracy, welding stability and intelligent functions. The product integrates DSP control, servo system and multi-frequency welding technology, has the ability to monitor and trace welding quality, supports industrial interconnection and automation, fully meets the needs of high-end precision welding, and demonstrates China's intelligent manufacturing strength.

The precision resistance spot welding machine is equipped with an intelligent power supply and monitor to achieve multi-stage slow-controlled discharge and low-heat welding. The solder joints are strong and beautiful, and the defective rate is reduced by 80%, reshaping the quality benchmark for 18650 battery welding!

The Hanoi Industrial Exhibition in Vietnam has come to an end. Products such as welding power supplies, transformers, spot welding machines, and monitors have been favored by many potential customers. Their advantages such as high efficiency, energy saving, precision and intelligence have been recognized, and customers are willing to further explore the technology.

The multi-point precision welding power supply has excellent functions, 6 control modes, 5 optional frequencies, supports multi-stage welding, has pressure triggering, etc., can weld efficiently and accurately, and ensure product quality.

Urwelder Welding Technology Co., Ltd. will be present at the Hanoi Industrial Exhibition in Vietnam with its self-developed precision resistance welding power supply, all-round welding detector and other products, leveraging the traffic of 20,000 visitors to expand the international market and enhance brand and product awareness.

Digital spot welding power supplies significantly improve welding quality and efficiency with high-precision control and intelligent algorithms. They are suitable for precision welding, spot welding, butt welding and roll welding scenarios, and promote the intelligent upgrading of the manufacturing industry.

Urwelder will present IDP/IDW/IAW intelligent welding power supplies, monitors and group control systems at VINAMAC EXPO, driving the digitalization and lean upgrading of ASEAN industries with high-precision welding technology.

We have been deeply engaged in the field of welding, constantly breaking through technical bottlenecks, and launching new products such as the IDP series welding power supplies, welding transformers, welding heads, monitors, etc., to achieve both performance and intelligence improvements, and comprehensively help welding applications in multiple industries reach new heights.

We will participate in the Hanoi Welding Exhibition in May 2025, Vietnam, to showcase advanced equipment such as DC and AC welding power supplies, welding transformers, resistance spot welders and welding monitors.

Urwelder releases IDP series high-frequency inverter DC power supply, which adopts high-frequency inverter and DSP technology, 0.2 millisecond precision control, imported components to ensure stability, and is suitable for precision welding scenarios such as automobiles and 3C electronics, promoting intelligent and efficient production.

China's top welding power supply and spot welding machine manufacturer appeared at the Kielce Spring Industrial Exhibition in Poland, demonstrating its core technologies and intelligent solutions, which won praise from customers. On-site practical operations promoted transactions and exhibition expectations were achieved.