- Home

- >

News

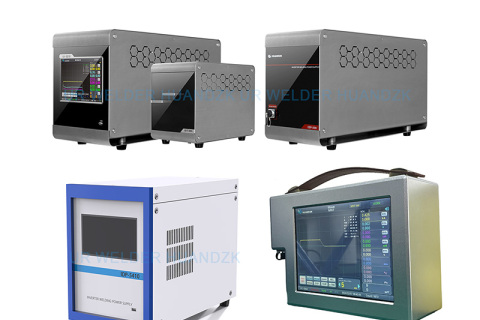

When choosing a lithium battery spot welding machine welding power supply, you need to consider the welding effect, scope of application and cost. Capacitor energy storage, inverter and AC welding power supplies each have their own advantages, suitable for different scenarios and meet diverse needs.

Inverter spot welding power supply has high-quality service and full life cycle guarantee. Features in the new energy field: medium frequency inverter is energy-saving and efficient, suitable for high-precision welding; supports lightweight materials and prevents thermal changes; integrated monitoring, high safety standards; small size, improved automation.

Ur welder provide high power high frequency DC welding power supplies, resistance spot welders, resistance weld monitorings, and professional customized automotive suspension spot welding solutions to ensure efficient and stable welding.

In 2025, the welding equipment industry is moving towards a new stage of precision, efficiency, intelligence and greening. Technological innovation leads the industry upgrade, and the market demand is strong, which promotes the high-quality development of the industry.

High-power inverter DC welding power source adopts advanced inverter technology, provides six control modes and five operating frequencies, ensuring stable and efficient welding process. It is widely used in automobile, shipbuilding and other fields to improve welding quality and efficiency.

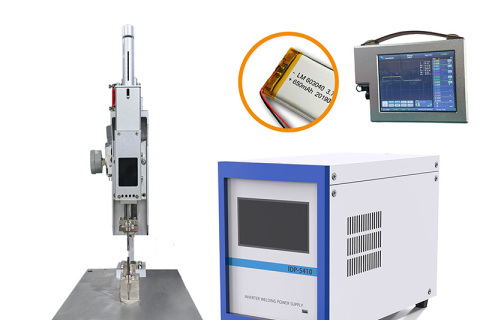

Precision spot welding machines are divided into resistive, capacitive energy storage and laser spot welding systems, suitable for different industrial scenarios. Huandian Intelligence provides energy-efficient and intelligently controlled spot welding solutions to meet the needs of new energy, 3C electronics and other industries.

Precision resistance welding machines are widely used in the electronics, battery, automotive and medical industries. With high-precision welding power supplies, welding transformers and welding monitors, they can achieve efficient and stable welding and help upgrade smart manufacturing.

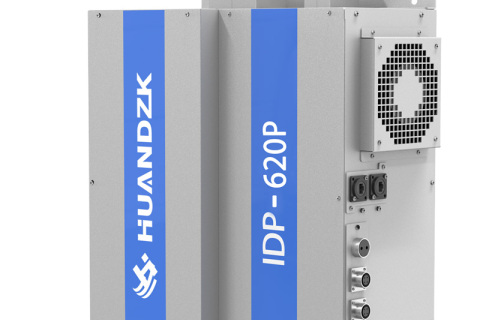

IDP series inverter DC welding power supply has the advantages of high-precision control, strong welding stability, multi-stage adjustable pressure, intelligent management and multi-frequency switching, which can adapt to complex welding needs.

During the Spring Festival holiday from January 20 to February 5, 2025, we suspended production but the business team was on standby. The core products include welding power supplies and intelligent solutions, with innovative functions such as multi-stage welding and servo control.

We will showcase its advanced IDP series precision welding power supplies at the Poland International Welding Technology and Equipment Exhibition. With precise control, intelligent monitoring and innovative technology, it will promote the development of the welding industry and provide efficient and stable intelligent welding solutions.

China's leading welding power supply manufacturer participated in the Kielce International Welding Fair in Poland, focusing on ultra-precision, inverter, high-frequency DC welding power supplies and intelligent welding solutions, demonstrating its technological innovation capabilities.

The precision spot welding machine adopts advanced inverter power supply, with stable heat output and fast response; the welding wire does not need to be processed and the operation is efficient; the welding wire diameter range is wide and applicable to many scenarios;