- Home

- >

News

380V copper wire welding machine is known for its high efficiency and reliability, and is widely used in the fields of electronics and electrical appliances. Its high-precision welding technology ensures quality and is suitable for copper wires of multiple specifications. When choosing, you need to consider power, technical parameters and brand quality. Huandian IDP series inverter DC welding power supply uses imported components and advanced technology to provide precise control and low-damage welding, helping enterprises to produce efficiently.

High-efficiency welding inverter transformer technology combined with a stable spot welding power supply enhances MFDC spot welding machine automotive applications and roller spot welding machines. Integrated capacitor discharge welding monitors provide real-time quality control, consistent energy output, and improved welding reliability for demanding industrial and automotive production environments.

Urwelder provides advanced transformer for welding machine and welding power supply solutions for industrial manufacturing, Electric vehicle battery pack welding, and handheld tack welder applications, delivering stable welding machine power supply performance, high efficiency, precise control, and reliable weld quality for modern, high-demand production environments.

advanced precision resistance welder technology, highlighting the role of intelligent welding power supply design, micro welding equipment, automatic welding system integration, and temperature curve control. It explains how these technologies improve welding accuracy, consistency, automation efficiency, and process stability in high-end industrial manufacturing applications.

Discover professional automotive welding solutions featuring a pro spot welder for sale, micro spot welder, robotic spot welding, and 3 phase spot welder technologies. Powered by an automotive welding power supply with monitoring system, these solutions deliver precision, stability, real-time quality monitoring, and high-efficiency production for modern automotive manufacturing.

A capacitive discharge welding power supply enables ultra-stable welding performance for precision metals, battery tabs, sensors, and micro-electronics. By delivering high peak energy through a controlled discharge, it improves consistency, reduces heat influence, and enhances weld quality. This article explains its advantages, control principles, applications, and a comparison with traditional resistance welding systems.

A battery tab welding solution using robotic welding system, advanced welding power supply, nickel tab welding machine, and welding current controller. The integration ensures precise, repeatable welds, minimizes thermal impact, and enhances production efficiency. This solution is ideal for automated battery assembly and large-scale energy storage manufacturing lines.

A modular welding power supply for battery pack production lines. By combining battery pack welding line, ultra-fast welding system, pulse energy storage welder, and welding quality monitor, manufacturers can achieve precise, repeatable welds at high speed. This solution improves automation, reduces defects, and enhances overall energy storage manufacturing efficiency.

This article examines the role of the high-precision welding DC power supply in advanced micro-joining applications. It details how the DC precision welding transformer and precision DC welding system improve weld quality, minimize spatter, and maintain stable current. The discussion highlights why industries increasingly rely on the direct current welding power unit to achieve consistent and reliable performance.

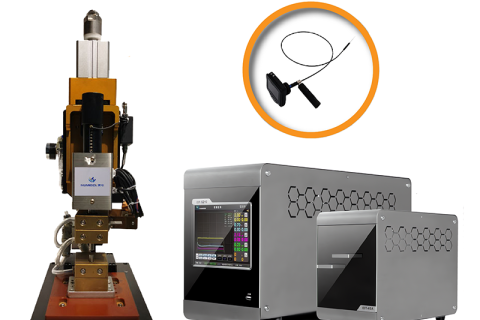

At the Canton Fair 2025, China’s leading welding power supply manufacturer will exhibit advanced Pulse Hot Press Welding systems, Resistance Spot Welders, and Welding Monitoring Instruments. With self-developed control and precision technology, the company brings smart, efficient welding solutions for global electronics, automotive, and new energy industries.