- Home

- >

News

We will showcase its advanced IDP series precision welding power supplies at the Poland International Welding Technology and Equipment Exhibition. With precise control, intelligent monitoring and innovative technology, it will promote the development of the welding industry and provide efficient and stable intelligent welding solutions.

China's leading welding power supply manufacturer participated in the Kielce International Welding Fair in Poland, focusing on ultra-precision, inverter, high-frequency DC welding power supplies and intelligent welding solutions, demonstrating its technological innovation capabilities.

The precision spot welding machine adopts advanced inverter power supply, with stable heat output and fast response; the welding wire does not need to be processed and the operation is efficient; the welding wire diameter range is wide and applicable to many scenarios;

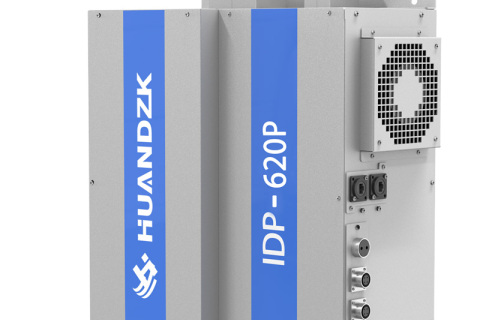

IDP-620 welding power system is specially customized for welding of automotive parts. It features high-precision digital control, intelligent operation, stability and reliability. It is suitable for a variety of welding processes, is highly efficient and energy-saving, and has comprehensive safety protection, facilitating high-quality production.

The combination of hanging welding clamp and resistance spot welding machine improves welding accuracy and efficiency. The hanging welding clamp provides a stable operating platform to reduce operator fatigue, while the resistance spot welding machine ensures high-quality welding, which is suitable for high-precision mass production and is widely used in the automotive, electronics and other industries to promote the automation and precision of production lines.

Precision DC spot welding machine, efficient and accurate, environmentally friendly and energy-saving. DC output, concentrated heating, good forming, traceless welding; high-precision control, fast response, high thermal efficiency; compact structure, easy operation, adaptable to a variety of environments, widely used in the field of precision welding.

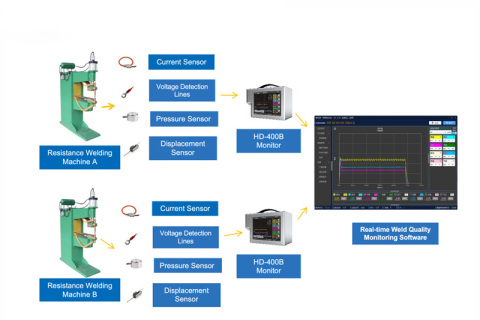

A magical tool for monitoring resistance welding machines, compatible with multiple types, capable of measuring current, voltage and power, alarming within seconds of exceeding the limit, storing millions of data, and keeping track of welding quality!

The precision resistance welding equipment integrates intelligent monitoring, real-time detection of current, voltage and other parameters, automatic alarm when exceeding the limit and rejection of defective products; built-in large-capacity database stores welding data and fault records, supports USB flash drive export and analysis; multi-stage welding is combined with slow rise and slow fall technology to effectively reduce spatter and improve welding stability.

Inverter DC welding power source is leading the innovation of welding technology with its advantages of high efficiency, stability and energy saving. Whether inverter welding power supply is improving welding quality or extending equipment life, inverter welding power supply welding equipment has brought significant benefits to modern manufacturing industry. Choosing inverter DC welding power source is undoubtedly a wise move towards efficient welding production.

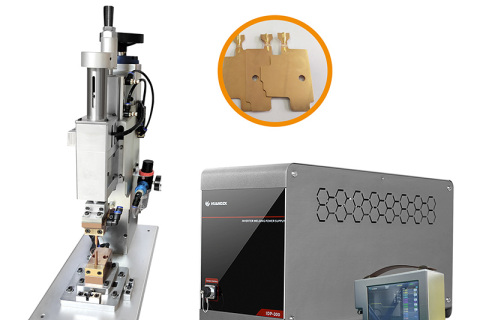

The precision welding spot welding machine adopts 0.2 millisecond high-precision control and servo pressure system, combined with mechanical positioning and electrical signal detection dual anti-reverse technology, to achieve low thermal damage and high stability in nut welding. The strength of the weld is more than 90% of the parent material, and the defective rate is less than 0.5%. It is widely used in high-precision manufacturing fields such as automobiles and electronics.

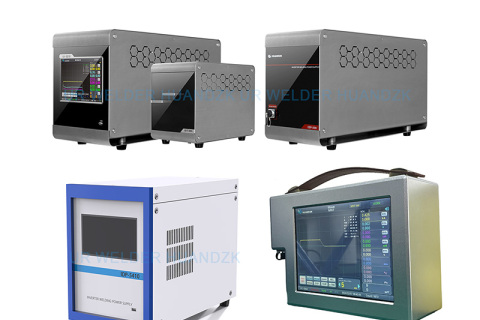

We provide advanced welding solutions, including precision power supplies, spot welding power controller, spot welding machine transformer, and welding quality inspection device. Our products enhance welding quality, control, and efficiency, offering real-time monitoring, data analysis, and network integration for improved performance and traceability.

The welding quality monitoring system can collect and display the key parameters such as welding current and voltage of single or multiple resistance welding equipment in real time. Welding quality monitoring system has over-limit alarm and network communication capabilities, can record data and support historical tracing.