- Home

- >

News

Searching for the best automotive resistance welding solution for EV motor stator resistance welding? As a China automotive welding machine manufacturer, we provide advanced automotive resistance welding technology and act as a trusted automotive spot welding equipment supplier for global EV production lines.

advanced precision resistance welder technology, highlighting the role of intelligent welding power supply design, micro welding equipment, automatic welding system integration, and temperature curve control. It explains how these technologies improve welding accuracy, consistency, automation efficiency, and process stability in high-end industrial manufacturing applications.

Explore the latest pedal pair welding machines and welding transformer manufacturers at the Canton Fair, featuring high-efficiency welding equipment for resistance welding that delivers precision, durability, and intelligent control for modern industrial applications.

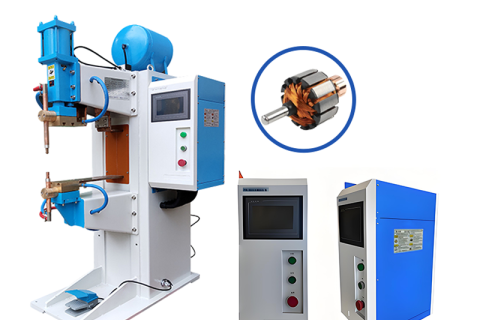

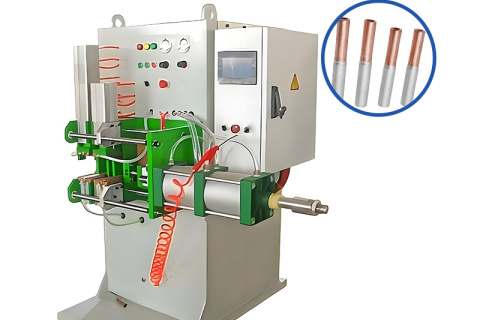

Our welding solutions include the resistance roll welding machine, resistance bumper welding machine, and industrial pneumatic spot welding machine, powered by advanced welding machine power supply systems. These machines ensure precision, strength, and efficiency, serving automotive, electronics, and industrial sectors with reliable weld quality, productivity, and long-term performance.

The HT-300 and HT-500 hot-press welding equipment combine precision resistance welding with servo motor control to provide high-precision, high-efficiency, and traceable welding solutions for a wide range of applications in the electronics, automotive, and new energy industries.

The pulse hot pressure welding power supply created by the resistance welding manufacturer has precise temperature control and strong adaptability of the welding head. It is suitable for electronics, automobiles, new energy and other fields, providing stable and efficient welding solutions and perfect after-sales service.

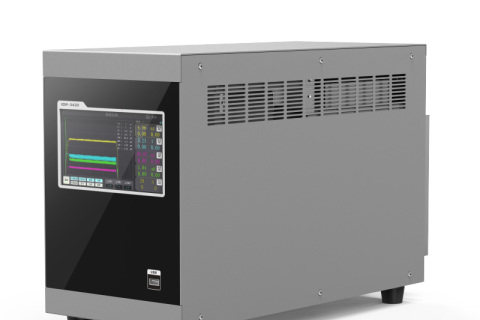

This spot welder is equipped with a high-precision IDP-8210 precision resistance welding power supply, which has the function of accurately judging welding quality. It supports multi-stage discharge and slow rise and fall, effectively avoiding current shock and ensuring stable and consistent welding. It supports host computer group control to achieve centralized management of multiple machines.

Urwelder is a high-tech enterprise specializing in the R&D and manufacturing of resistance welding systems. With a strong technical team and fully independent intellectual property, we offer a full range of advanced products including welding controllers, power supplies, and precision spot welders. Our solutions compete with top global brands and are trusted by high-end clients worldwide.

Ur Welder will bring high-end products such as welding transformers, controllers, and monitors to the Shanghai Automotive Welding Exhibition, with performance exceeding Miyachi, helping customers improve efficiency and welding quality.

At the 25th Moscow International Metalworking Exhibition, the independently developed IDP series high-frequency inverter DC welding power source stood out with its high control accuracy, welding stability and intelligent functions. The product integrates DSP control, servo system and multi-frequency welding technology, has the ability to monitor and trace welding quality, supports industrial interconnection and automation, fully meets the needs of high-end precision welding, and demonstrates China's intelligent manufacturing strength.

Precision resistance welding is widely used in the field of electric motors. It can accurately weld commutators and other components in rotor manufacturing, and ensure that windings and other components are firmly connected and of stable quality in stator production.

Digital spot welding power supplies significantly improve welding quality and efficiency with high-precision control and intelligent algorithms. They are suitable for precision welding, spot welding, butt welding and roll welding scenarios, and promote the intelligent upgrading of the manufacturing industry.