- Home

- >

News

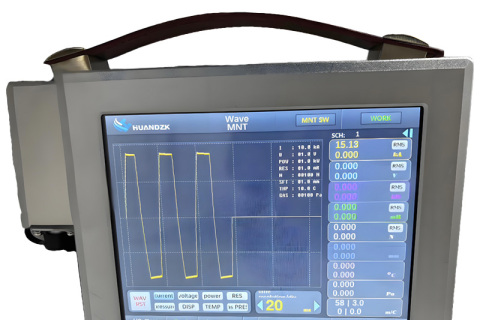

The welding quality monitoring system can collect and display the key parameters such as welding current and voltage of single or multiple resistance welding equipment in real time. Welding quality monitoring system has over-limit alarm and network communication capabilities, can record data and support historical tracing.

The HD-400B welding monitoring device has the following notable advantages: high-precision real-time monitoring, comprehensive data analysis, wide applicability, excellent standard discrimination, large-screen viewing display, enhanced data traceability, rich communication interfaces and efficient statistical monitoring.

Weld penetration is a key indicator to measure the quality of resistance welding and is significantly affected by factors such as current and pressure. Advanced testing equipment can monitor welding parameters in real time, accurately determine quality and trace data, comprehensively improving welding strength, sealing and service life.

Huandian specializes in the manufacture of high-precision spot welding machines, providing a variety of excellent performance equipment with ultra-high welding accuracy and powerful quality monitoring systems. Through continuous research and development and innovation, Huandian leads the industry in welding control accuracy, functional stability and production efficiency to meet the diverse needs of customers.

Welding detector is suitable for a variety of resistance welding machines and can comprehensively monitor all kinds of data (partially optional). It also has a powerful database function, can record a large amount of welding and fault information, and supports USB flash drive export, which is convenient for quality monitoring and tracking.

Our core products include ultra precision welding power supplies, precision inverter welding power supplies, high power high frequency DC welding power supplies, high frequency transformers and other hardware essentials; at the same time, we also provide intelligent solutions such as multi functional welding monitors, welding networking group control systems and welding quality monitoring systems

The operation of the spot welding machine requires carefulness and patience. The key is to accurately adjust the welding parameters. Safety must be ensured and the parameters must be adjusted according to the product characteristics. Readjust the parameters when changing products and follow the safety manual to ensure welding quality and improve production efficiency.

When using the copper wire spot welding machine, you need to pay attention to equipment inspection, copper wire selection, safe operation and maintenance to ensure welding quality, operational safety and stable operation of the equipment.

Current detection of precision spot welding machines is the key to ensuring welding quality. Oscilloscope testing may not be accurate, so it is recommended to use a dedicated current tester for monitoring. When purchasing, companies should choose equipment equipped with a current tester and conduct regular testing and calibration to ensure the stability and reliability of welding quality.