- Home

- >

News

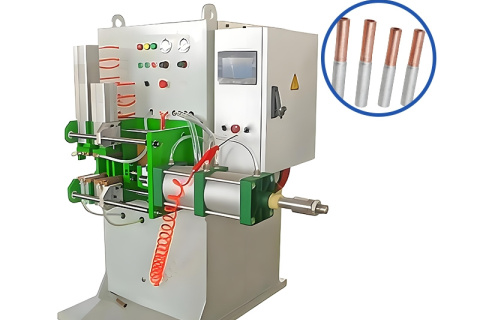

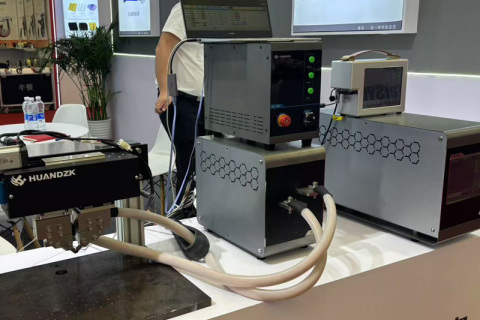

The core equipment like copper bar resistance welding machine and inverter resistance welding machine, paired with seam welding control and resistance sensors, empowering manufacturing efficiency and precision.

This integrated solution features a resistance welding analyzer, durable resistance welding electrodes, resistance welding press multifunctional, spot welding machine small, and long seam welding machine. It ensures precise weld monitoring, versatile production capabilities, and high-quality results for automotive, electrical, and industrial applications.

This overview introduces professional welding quality monitoring solutions, including nut welding monitoring system, seam welding quality control, capacitor discharge welding monitor, micro spot welding quality tester, and inverter resistance welder monitor. It highlights how real-time data acquisition, process monitoring, and traceability improve weld consistency, defect detection, and overall manufacturing reliability across industrial welding applications.

Automotive resistance welding, including spot, projection, and seam techniques, is vital for assembling durable car bodies and components. These methods ensure precision, speed, and leak-proof bonds, supporting safety and efficiency in modern vehicle manufacturing, especially for EVs.

A roller spot welder and roll welding machine deliver stable, precise roll seam welding for metal fabrication. Many buyers compare roll spot welding machine price to select the most efficient roll spot welder. With continuous seam quality and strong welding performance, these machines improve productivity and guarantee reliable welding results.

A high-performance roller welding machine, handwheel rolling and welding machine, and solutions from reliable seam welding machine manufacturers enhance modern metal processing. With specialized systems such as a copper wire seam welding machine and a metal box seam welding machine, factories achieve stable weld seams, improved efficiency, and consistent product quality across diverse industrial applications.

This article introduces advanced welding solutions including the automatic seam welding machine, automatic roll welding machine, horizontal seam welding machine, circular seam welding machine, and straight seam welding machine. These systems improve welding precision, boost productivity, and support automated manufacturing across industries such as automotive, HVAC, stainless-steel processing, and pressure vessel production.

This article highlights the advantages of seam welding machine technologies, including longitudinal seam welding machines, rolling welding machine systems, rolling spot welding machine equipment, seam welding machine longitudinal designs, and longitudinal welding machine automated welding machine solutions. These advanced machines improve welding accuracy, production efficiency, and long-term reliability across metal manufacturing industries.

Professional welding power supply manufacturer providing hot bar soldering machine, resistance spot welding machines, and precision resistance welding solutions worldwide.

2025’s top stainless welding tech: best welder for stainless steel, automatic roll welding machine, roll spot and seam welding, fusion welding machine, resistance weld monitoring — boost precision, speed & smart control.

The five core elements of 2025 stainless steel welding: optimized welding machine, automatic roll welding, roller spot welding, fusion technology, and resistance welding monitoring, comprehensively improve efficiency, precision, and intelligence, and help upgrade high-end manufacturing.

Servo clamp welding tandem spot welding machine has precise and controllable pressure, concentrated energy, less spatter, stable and reliable welding, and is suitable for high thermal conductivity materials such as copper and aluminum and precision welding applications.