- Home

- >

News

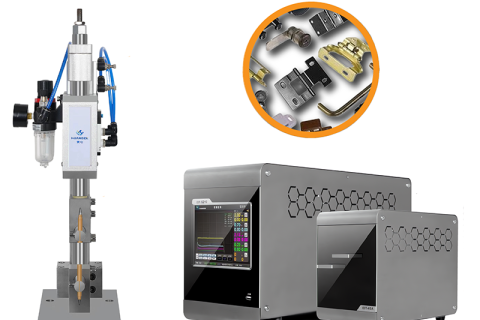

The combination of hanging welding clamp and resistance spot welding machine improves welding accuracy and efficiency. The hanging welding clamp provides a stable operating platform to reduce operator fatigue, while the resistance spot welding machine ensures high-quality welding, which is suitable for high-precision mass production and is widely used in the automotive, electronics and other industries to promote the automation and precision of production lines.

Weld penetration testing methods include metallographic microscope observation, compression test and weld penetration microscope observation. Weld penetration tester measures the temperature change during welding through thermocouples, and the computer analyzes the data to determine the penetration depth. Resistance welding penetration tester helps to optimize welding parameters, monitor the welding process in real time, and ensure welding quality.

Precision inverter welding equipment has been launched, which improves welding stability and efficiency with a high control accuracy of 0.2 milliseconds. It is widely used in industries such as automobiles, motors, capacitors, solar energy and batteries, promoting industrial upgrading and the development of intelligent manufacturing.