How Does a Steel Wire Butt Flash Welding Machine Improve Rebar Butt Joint Welding Efficiency?

2025-12-24 21:38Steel Wire Butt Flash Welding Machine: A Reliable Solution for High-Strength Butt Joint Welding

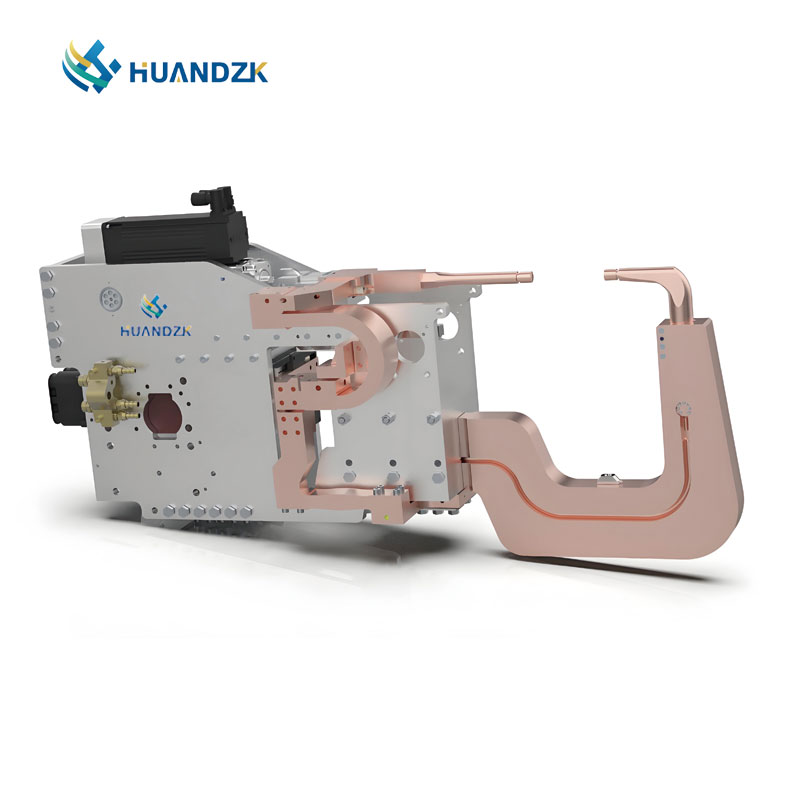

In modern construction, steel processing, and infrastructure manufacturing, welding quality directly determines structural safety and long-term reliability. The steel wire butt flash welding machine has become a preferred solution for high-strength butt joint welding, especially where consistency, efficiency, and mechanical performance are critical. From reinforcing steel bars to industrial wire products, butt welding technology continues to replace traditional joining methods.

A steel wire butt flash welding machine operates by generating controlled flashing at the joint interface, followed by rapid upsetting. This process removes surface oxides and contaminants, creating a solid-state metallurgical bond. Compared with conventional arc welding, butt joint welding using flash technology delivers higher tensile strength, excellent alignment, and minimal material loss.

Rebar Contact Butt Welding Machine for Construction Applications

In the construction and prefabrication industries, the rebar contact butt welding machine is widely used for joining reinforcing bars efficiently and reliably. Unlike overlap welding, rebar contact butt welding produces a straight, continuous load path, which is essential for reinforced concrete structures.

A modern rebar contact butt welding machine ensures uniform heat distribution and precise pressure control during welding. This results in consistent weld penetration and eliminates weak points caused by uneven fusion. Compared with manual welding methods, automated butt joint welding significantly improves productivity while reducing dependence on skilled labor.

The growing demand for large-scale infrastructure projects has made rebar contact butt welding machines an indispensable part of steel processing lines worldwide.

Butt Joint Welding vs. Butt Fusion Welding

When selecting a welding solution, manufacturers often compare butt joint welding with butt fusion welding. Butt fusion welding is commonly used for thermoplastic pipes, where materials are melted and pressed together under controlled conditions. However, for metallic materials such as steel wire and rebar, butt fusion welding is not suitable.

In contrast, butt joint welding using a steel wire butt flash welding machine or rebar contact butt welding machine is specifically designed for metal joining. Flash butt welding achieves a refined grain structure at the joint, ensuring superior mechanical strength compared with fusion-based methods. This makes butt joint welding the preferred choice for load-bearing steel components.

Performance Advantages of Butt Welding Machines

A high-quality butt welding machine offers multiple advantages across industrial applications:

High welding efficiency for mass production

Strong and uniform butt joint welding quality

Minimal heat-affected zone and distortion

Reduced electrode consumption

Stable performance under continuous operation

These benefits make the steel wire butt flash welding machine suitable for wire drawing plants, mesh production, fastener manufacturing, and automotive component suppliers. Similarly, the rebar contact butt welding machine is widely adopted in construction steel processing centers and precast concrete factories.

Understanding Butt Welding Machine Price and Value

When evaluating a butt welding machine price, buyers should look beyond initial equipment cost. Factors such as welding capacity, automation level, energy efficiency, and long-term maintenance play a crucial role in overall return on investment.

Although advanced butt joint welding equipment may have a higher upfront butt welding machine price, it delivers lower operating costs through reduced scrap rates, faster cycle times, and longer service life. A well-designed steel wire butt flash welding machine can operate reliably for years with minimal downtime, making it a cost-effective solution in high-volume production environments.

Additionally, customizable configurations allow users to select machines that best match their application, helping balance performance and butt welding machine price.

Industry Applications and Market Trends

The demand for butt joint welding solutions continues to grow across industries such as construction, infrastructure, transportation, and energy. Steel wire butt flash welding machines are increasingly used in the production of wire mesh, fencing, and industrial springs. Rebar contact butt welding machines support the rapid expansion of high-rise buildings, bridges, and rail projects.

With stricter quality standards and rising labor costs, manufacturers are shifting toward automated butt welding systems that ensure repeatable results. Compared with traditional welding methods, butt joint welding provides superior mechanical performance while meeting international construction and safety standards.

Conclusion

Whether for steel wire processing or rebar joining, the steel wire butt flash welding machine and rebar contact butt welding machine offer proven solutions for reliable butt joint welding. Compared with butt fusion welding, these machines are specifically engineered for metal applications, delivering stronger joints and higher efficiency. When evaluated correctly, the butt welding machine price reflects not only equipment cost, but long-term productivity, quality, and operational stability—making butt welding technology a smart investment for modern industry.