Cold Roll forming Equipment

2024-01-22 19:15Cold roll forming equipment is machinery used in the process of cold roll forming, a metal forming technique that involves shaping metal sheets or strips at room temperature through a series of continuous bending operations. This process is commonly used to produce long sections with a consistent cross-section profile, such as metal roofing, wall panels, steel studs, and other structural components.

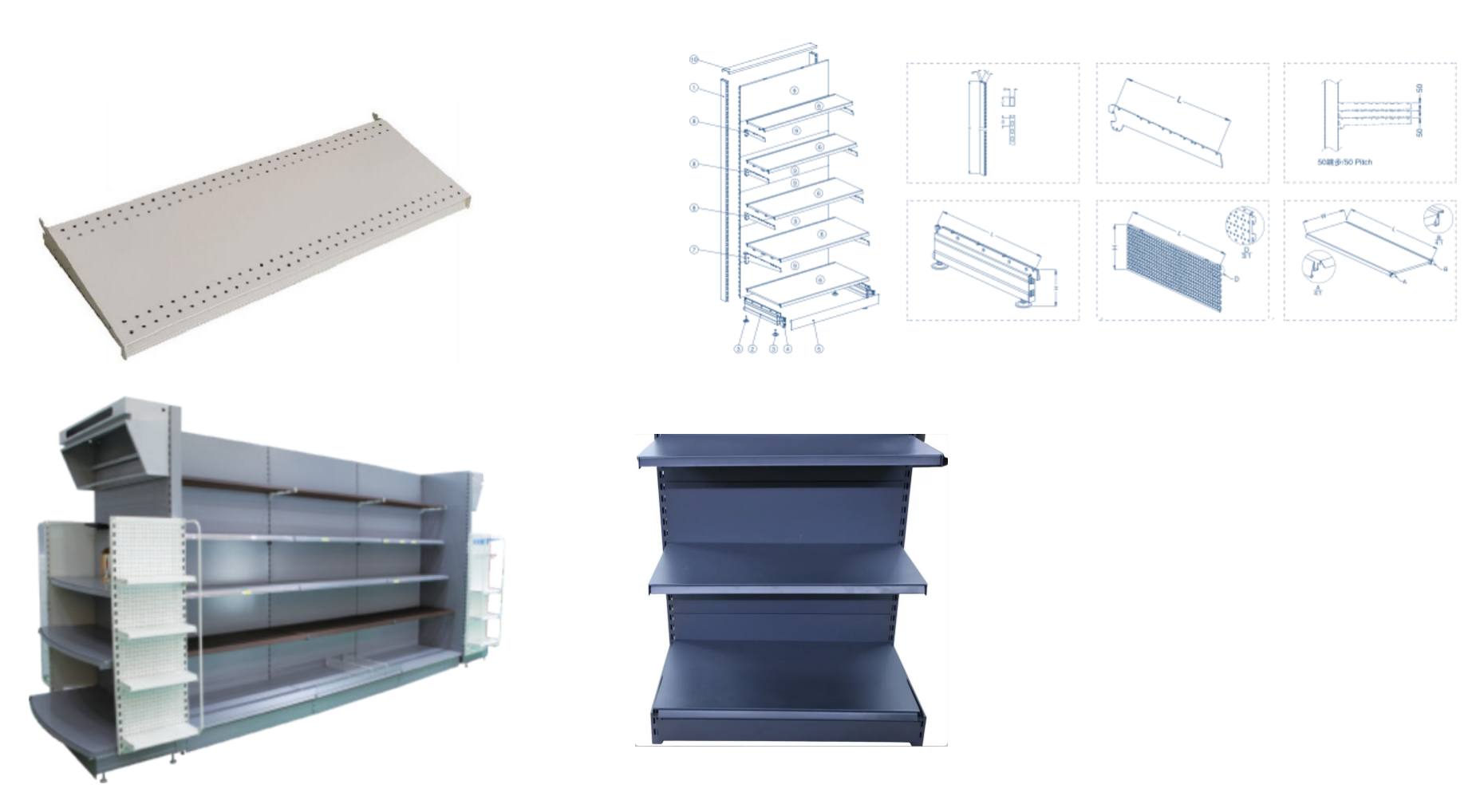

Key components of cold roll forming equipment typically include:

Uncoiler/Decoiler: This is where the raw material, usually a metal coil, is loaded and fed into the roll forming machine.

Leveler/Flattener: The material may go through a leveler or flattener to ensure that it is straight and has uniform thickness before entering the forming rolls.

Roll Forming Mill: This is the heart of the cold roll forming equipment. The mill consists of a series of paired rollers that gradually shape the metal into the desired cross-sectional profile. The number and arrangement of the rollers depend on the specific profile being formed.

Guiding System: Guides help to ensure the proper alignment of the material as it passes through the forming rolls.

Cut-off Tool: After the material has been formed, a cut-off tool is used to shear it into the desired lengths.

Control System: Modern cold roll forming equipment often comes with computerized control systems that allow operators to set and adjust various parameters, such as roller positions, speeds, and cut-off lengths.

Exit Equipment: This includes systems for collecting and stacking the finished products.

The advantages of cold roll forming include high production speeds, the ability to form complex shapes, and the possibility of forming long lengths of material with a consistent profile. Additionally, since the process is performed at room temperature, there is less material distortion and better surface finish compared to hot rolling.

The specific features and capabilities of cold roll forming equipment can vary depending on the manufacturer and the intended application. When selecting cold roll forming equipment, it's important to consider factors such as the required profile, material thickness, production speed, and the overall quality of the equipment.