- Home

- >

News

At booth 1A-A16 at the Polish Spring Industrial Exhibition, welding power supply manufacturers will showcase their cutting-edge welding technology matrix, with independent research and development, international quality, and intelligent monitoring to help reduce costs and increase efficiency.

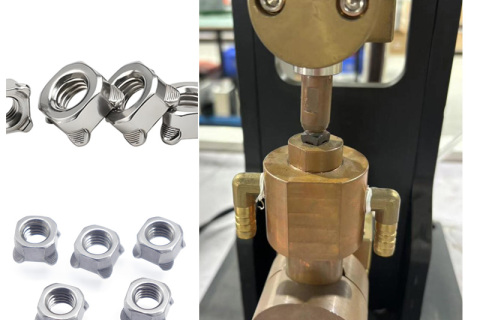

The nut error prevention monitoring system integrates error prevention, counting and management. It uses high-precision sensors and MCU to ensure that the nut welding is correct, improve production efficiency and quality, and meet diversified production needs.

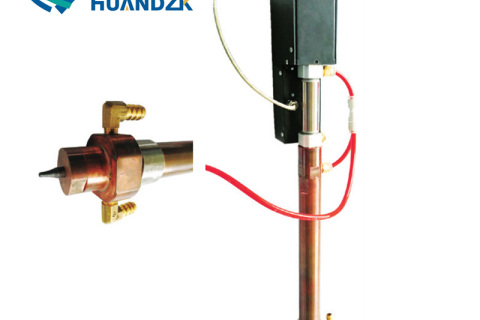

The projection welding nut error-proofing detector improves welding quality and efficiency, prevents errors, and helps efficient production. Projection welding nut error-proofing detector is a powerful assistant and high-quality equipment in industrial production.

Huandian HD-400B welding monitor leads the industry with accurate monitoring, intelligent judgment, powerful database and user-friendly design. Weld data monitoring comprehensively covers welding parameters, provides real-time warning of unqualified products, and supports efficient quality traceability. Welding leakage detector is an ideal choice for welding quality control.

The HD-400B all-purpose welding detector has real-time data collection, quality judgment, high-definition touch display and powerful database functions, supports a variety of equipment and communication protocols, and comprehensively improves welding quality management and production efficiency.

Welding detector is suitable for a variety of resistance welding machines and can comprehensively monitor all kinds of data (partially optional). It also has a powerful database function, can record a large amount of welding and fault information, and supports USB flash drive export, which is convenient for quality monitoring and tracking.

In the field of precision hot-press welding, the selection of welding power source is crucial. AC power source has low cost but low control accuracy and high energy consumption; while inverter power source has complex structure but high control accuracy, fast and stable heating speed and low energy consumption. Therefore, inverter DC welding power source has gradually become the mainstream choice in the field of precision welding and is widely used in many welding fields.