- Home

- >

News

This article introduces five major resistance welding head types—pneumatic welding head, servo welding head, roll welding head, hot bar welding head, and projection welding head. Designed for precision manufacturing, they deliver stable force control, consistent weld formation, long-term reliability, and seamless integration with modern automation lines for electronics, automotive, and battery production.

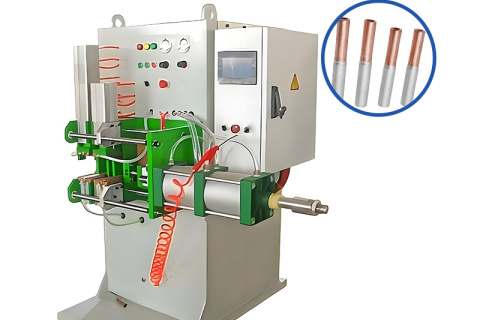

A roller spot welder and roll welding machine deliver stable, precise roll seam welding for metal fabrication. Many buyers compare roll spot welding machine price to select the most efficient roll spot welder. With continuous seam quality and strong welding performance, these machines improve productivity and guarantee reliable welding results.

This article introduces advanced welding solutions including the automatic seam welding machine, automatic roll welding machine, horizontal seam welding machine, circular seam welding machine, and straight seam welding machine. These systems improve welding precision, boost productivity, and support automated manufacturing across industries such as automotive, HVAC, stainless-steel processing, and pressure vessel production.

Our welding solutions include the resistance roll welding machine, resistance bumper welding machine, and industrial pneumatic spot welding machine, powered by advanced welding machine power supply systems. These machines ensure precision, strength, and efficiency, serving automotive, electronics, and industrial sectors with reliable weld quality, productivity, and long-term performance.

2025’s top stainless welding tech: best welder for stainless steel, automatic roll welding machine, roll spot and seam welding, fusion welding machine, resistance weld monitoring — boost precision, speed & smart control.

The five core elements of 2025 stainless steel welding: optimized welding machine, automatic roll welding, roller spot welding, fusion technology, and resistance welding monitoring, comprehensively improve efficiency, precision, and intelligence, and help upgrade high-end manufacturing.

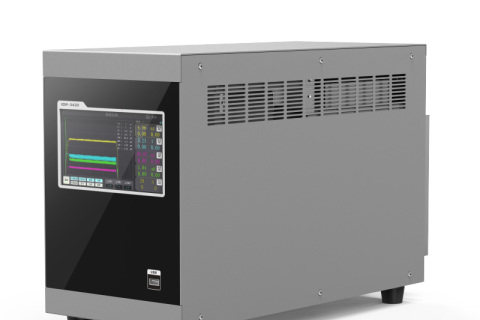

Digital spot welding power supplies significantly improve welding quality and efficiency with high-precision control and intelligent algorithms. They are suitable for precision welding, spot welding, butt welding and roll welding scenarios, and promote the intelligent upgrading of the manufacturing industry.