- Home

- >

News

Precision manufacturing benefits from spot welding thermocouple wires, stable resistance welding machine price, and accurate inverter resistance welder monitor control. Using an automated pulse welder and understanding capacitor discharge welding process explanation ensures consistent, high-quality welds. This integrated approach boosts efficiency, repeatability, and reliability across modern industrial and automotive production lines.

The core equipment like copper bar resistance welding machine and inverter resistance welding machine, paired with seam welding control and resistance sensors, empowering manufacturing efficiency and precision.

Urwelder delivers robotic resistance welding automation for automotive production, combining inverter resistance welding machine technology, stable welding resistance control, and efficient multi spot welding. Our metal welding machine solutions ensure high productivity, consistent weld quality, and reliable performance for modern automotive manufacturing lines.

At the 2025 Canton Fair (Oct 15–19, Guangzhou), China’s largest resistance welding power supply manufacturer presents its latest IDP series welding power supplies, welding monitors, pulse heat welding, and capacitor discharge welding systems—showcasing precision control, intelligent monitoring, and advanced welding technology for global industries including electronics, automotive, and energy applications.

Comprehensive resistance weld monitoring systems. Reliable resistance welding power supply technology. Durable butt resistance welding machine designs. Competitive china made spot welding machine solutions.

Huandzk/Urwelder's IDP system welding power supplies and IDP resistance spot welders, combined with spot weld testing equipments, leverage the technological advantages of the welding power supply manufacturer to deliver efficient, accurate, and traceable welding solutions, empowering smart manufacturing.

The IDP welding source sets new standards in the field of precision welding power supply. With advanced digital control and seamless servo head integration, it delivers higher accuracy and efficiency than miyachi, bosch, or any inverter welding power supply manufacturer. Designed for demanding industries, the IDP system offers reliability, data traceability, and cost-effective welding solutions.

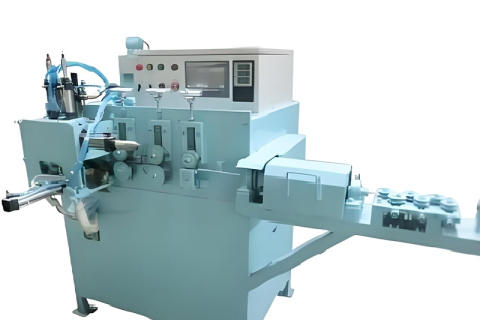

The Resistance welding machine, Pulse Thermocompression Welding, Pulse Heat (Hot Bar Reflow) Soldering Machine, Pulse Heat Bonding, and Hot Bar Welding, highlighting their applications, advantages, and role in modern electronics and metal joining industries.

Urwelder is a high-tech enterprise specializing in the R&D and manufacturing of resistance welding systems. With a strong technical team and fully independent intellectual property, we offer a full range of advanced products including welding controllers, power supplies, and precision spot welders. Our solutions compete with top global brands and are trusted by high-end clients worldwide.

Ur Welder will bring high-end products such as welding transformers, controllers, and monitors to the Shanghai Automotive Welding Exhibition, with performance exceeding Miyachi, helping customers improve efficiency and welding quality.