- Home

- >

News

Our welding solutions include the resistance roll welding machine, resistance bumper welding machine, and industrial pneumatic spot welding machine, powered by advanced welding machine power supply systems. These machines ensure precision, strength, and efficiency, serving automotive, electronics, and industrial sectors with reliable weld quality, productivity, and long-term performance.

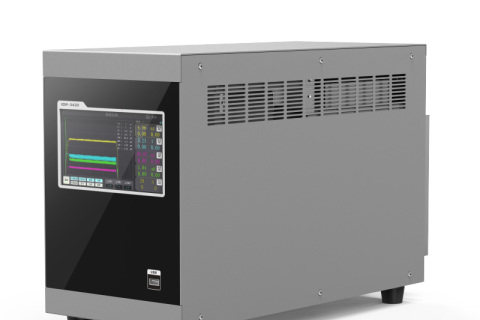

Digital spot welding power supplies significantly improve welding quality and efficiency with high-precision control and intelligent algorithms. They are suitable for precision welding, spot welding, butt welding and roll welding scenarios, and promote the intelligent upgrading of the manufacturing industry.

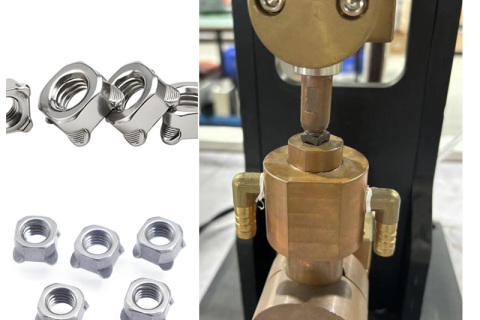

The projection welding nut error proofing detector improves welding quality and efficiency, prevents errors, and helps efficient production. Welding analyzer equipment is a powerful assistant and high-quality equipment in industrial production.

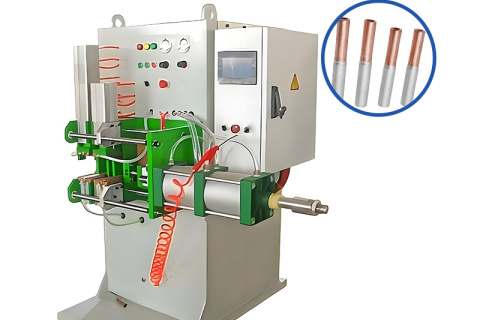

Copper wire terminal welding relies on a high-efficiency spot welding machine with a built-in special resistance welding transformer. Resistance spot welder uses the principle of resistance welding to achieve precise welding and ensure a firm connection.

In the field of precision hot-press welding, the selection of welding power source is crucial. AC power source has low cost but low control accuracy and high energy consumption; while inverter power source has complex structure but high control accuracy, fast and stable heating speed and low energy consumption. Therefore, inverter DC welding power source has gradually become the mainstream choice in the field of precision welding and is widely used in many welding fields.