- Home

- >

News

At the 25th Moscow International Metalworking Exhibition, the independently developed IDP series high-frequency inverter DC welding power source stood out with its high control accuracy, welding stability and intelligent functions. The product integrates DSP control, servo system and multi-frequency welding technology, has the ability to monitor and trace welding quality, supports industrial interconnection and automation, fully meets the needs of high-end precision welding, and demonstrates China's intelligent manufacturing strength.

Leading resistance welder manufacturers are showcasing innovations, including high-efficiency inverter welding machines, advanced welding power supplies, analyzers, and thermocouple spot welding equipment, revolutionizing industrial welding.

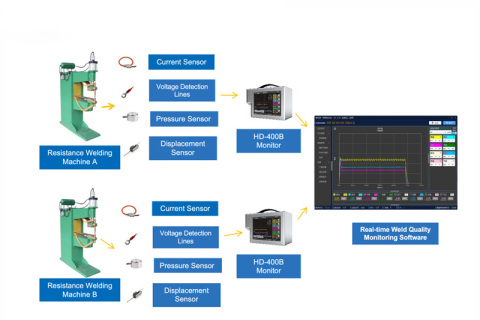

A magical tool for monitoring resistance welding machines, compatible with multiple types, capable of measuring current, voltage and power, alarming within seconds of exceeding the limit, storing millions of data, and keeping track of welding quality!

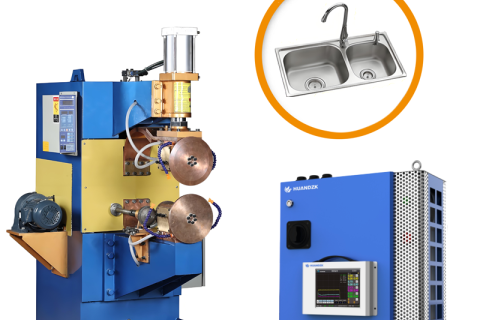

Features of the seam welding machine: high efficiency, stability, reliability, suitable for continuous welding of thin plate materials. Application areas: aerospace, automobile manufacturing, petrochemical and other industrial fields.