- Home

- >

News

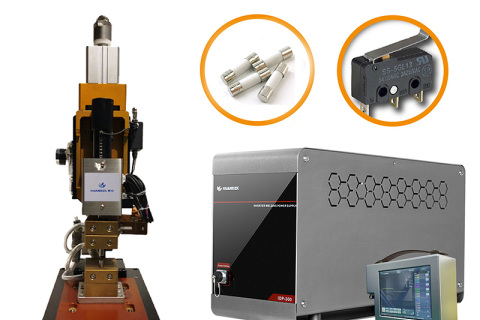

The HD-400B welding monitor has multi-parameter real-time monitoring, abnormal alarm, and quality judgment functions. HD-400B welding traceability system is compatible with a variety of spot welding models and is a key device for realizing intelligent welding and quality traceability.

The precision spot welding machine adopts 0.2 ms high-precision control 6 and servo pressure system, combined with mechanical positioning and electrical signal detection dual anti-reverse technology, to achieve low thermal damage and high stability in nut welding. The strength of the weld point reaches more than 90% of the parent material, and the defective rate is less than 0.5%. It is widely used in high-precision manufacturing fields such as automobiles and electronics.