- Home

- >

News

The IDP welding source sets new standards in the field of precision welding power supply. With advanced digital control and seamless servo head integration, it delivers higher accuracy and efficiency than miyachi, bosch, or any inverter welding power supply manufacturer. Designed for demanding industries, the IDP system offers reliability, data traceability, and cost-effective welding solutions.

Huandian/Urwelder IDP precision welding power supply, with built-in monitor and high-precision control, is specially designed for intelligent automotive manufacturing. It shined at the Essen Exhibition in Germany, reshaping the new standard of intelligent welding with its self-developed "Chinese core".

Urwelder and university doctors jointly developed the H-300 and H-500 pulse heating power supplies, integrating five-stage heating, full-process visualization, intelligent monitoring and MES interconnection to fully support high-end precision manufacturing.

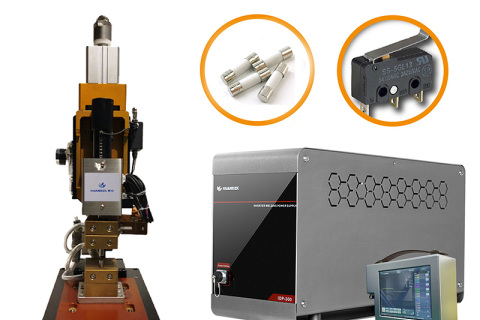

The precision spot welding machine adopts 0.2 ms high-precision control 6 and servo pressure system, combined with mechanical positioning and electrical signal detection dual anti-reverse technology, to achieve low thermal damage and high stability in nut welding. The strength of the weld point reaches more than 90% of the parent material, and the defective rate is less than 0.5%. It is widely used in high-precision manufacturing fields such as automobiles and electronics.

This welding equipment has a high-precision control of 0.2ms and low heat generation to create beautiful and stable solder joints. It integrates current, voltage, power, pressure, and displacement monitoring, and has pre-detection alarm and powerful quality traceability capabilities (recording more than 5 million data). The welding frequency can be flexibly switched between 1-5KHZ to meet various needs.

Efficient spiral spring production relies on integrated welding power supply & monitoring for precision welding & quality assurance.

Debuting at AMTS 2024, we will showcase innovative products such as precision welding power supplies, quality monitoring systems, and high-frequency transformers. We will focus on serving the high-tech manufacturing industry, provide customized welding solutions for high-end customers around the world, and promote the high-quality development of the manufacturing industry.

In the field of precision hot-press welding, the selection of welding power source is crucial. AC power source has low cost but low control accuracy and high energy consumption; while inverter power source has complex structure but high control accuracy, fast and stable heating speed and low energy consumption. Therefore, inverter DC welding power source has gradually become the mainstream choice in the field of precision welding and is widely used in many welding fields.