- Home

- >

News

At the 2025 Canton Fair (Oct 15–19, Guangzhou), China’s largest resistance welding power supply manufacturer presents its latest IDP series welding power supplies, welding monitors, pulse heat welding, and capacitor discharge welding systems—showcasing precision control, intelligent monitoring, and advanced welding technology for global industries including electronics, automotive, and energy applications.

Professional welding power supply manufacturer providing hot bar soldering machine, resistance spot welding machines, and precision resistance welding solutions worldwide.

The IDP welding source sets new standards in the field of precision welding power supply. With advanced digital control and seamless servo head integration, it delivers higher accuracy and efficiency than miyachi, bosch, or any inverter welding power supply manufacturer. Designed for demanding industries, the IDP system offers reliability, data traceability, and cost-effective welding solutions.

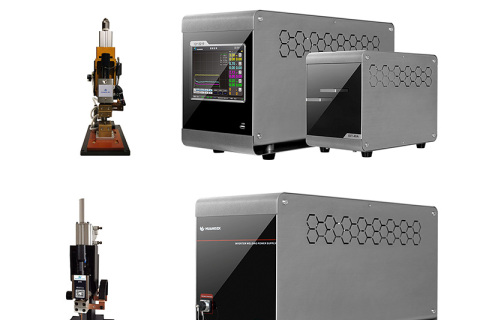

The IDP-1210 ultra-precision resistance welding power supply features 0.1ms control accuracy, supports multi-stage welding control and quality judgment, and offers stable, accurate and reliable welding, intelligent judgment, and multi-interface communication, making it suitable for demanding precision welding scenarios.

Huandian DC inverter welding power supply is efficient and stable, with high welding quality, convenient intelligent management, and guaranteed safety. Dc inverter welding power supply is suitable for high-quality welding needs, but the cost is relatively high.

Huandian has launched a high-precision welding power source, which is specially designed for new energy battery manufacturing to improve welding efficiency and quality. It has been widely used in many fields and has begun to produce products in factories in Indonesia, India, Brazil, Turkey, the United States, Vietnam and other countries. The quality is comparable to that of Miyachi and Bosch, and it has won the trust and praise of domestic and foreign customers.

Huandian IDP-300 is a high-precision welding power source with 6 control modes and 5 operating frequencies. Resistance welding power supports multi-stage adjustable welding pressure and has a built-in database function, making it suitable for complex welding conditions.

High-power inverter DC welding power source adopts advanced inverter technology, provides six control modes and five operating frequencies, ensuring stable and efficient welding process. It is widely used in automobile, shipbuilding and other fields to improve welding quality and efficiency.

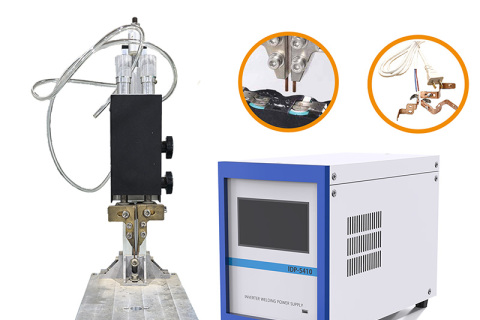

The precision welding spot welding machine adopts 0.2 millisecond high-precision control and servo pressure system, combined with mechanical positioning and electrical signal detection dual anti-reverse technology, to achieve low thermal damage and high stability in nut welding. The strength of the weld is more than 90% of the parent material, and the defective rate is less than 0.5%. It is widely used in high-precision manufacturing fields such as automobiles and electronics.

In the field of precision resistance welding, transistor-type welding power supplies are critical. They can adjust current and voltage and have many advantages, such as precise control and adjustable parameters. Although they have shortcomings, they and monitors help promote process development.

Resistance welding welding machine power supply melts metal locally by generating resistance heat through current passing through the workpiece, thus achieving welding. Resistance butt welding machine advantages include high efficiency, no need for filler materials, wide application range, and suitability for automated production; but precision resistance welding's disadvantages are that precision resistance welding machine has requirements on material thickness, the electrode wears quickly, and the joint appearance is poor.