- Home

- >

News

A capacitive discharge welding power supply enables ultra-stable welding performance for precision metals, battery tabs, sensors, and micro-electronics. By delivering high peak energy through a controlled discharge, it improves consistency, reduces heat influence, and enhances weld quality. This article explains its advantages, control principles, applications, and a comparison with traditional resistance welding systems.

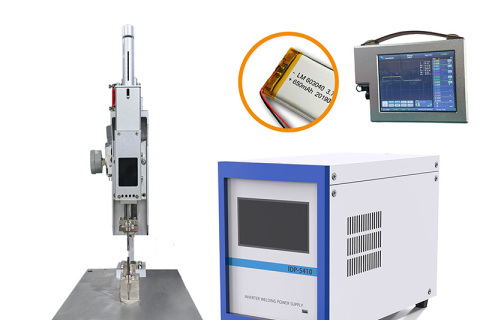

Our energy storage welding power supply delivers fast, stable, and consistent welding performance. Featuring capacitor discharge technology, it ensures high peak current, short welding time, and precise control. Ideal for battery tabs, connectors, and precision metal parts, it boosts efficiency while maintaining excellent quality and safety for modern automated production lines.

Huandian brought energy storage welding power supplies, pulse hot pressing welding, and welding monitors to the Essen exhibition, showcasing efficient and stable intelligent welding solutions to help upgrade the quality of industries such as automobiles, new energy, and electronics.

When choosing a lithium battery spot welding machine welding power supply, you need to consider the welding effect, scope of application and cost. Capacitor energy storage, inverter and AC welding power supplies each have their own advantages, suitable for different scenarios and meet diverse needs.