Professional Spot Welding Equipment for Automotive Body Frames and EV Battery Manufacturing

2025-12-19 20:21Precision Welding in Automotive Manufacturing: Techniques and Applications

The automotive manufacturing industry relies heavily on advanced joining technologies to ensure structural integrity, safety, and performance. Among these, resistance welding and its specific variant, spot welding, form the backbone of modern vehicle assembly, from traditional internal combustion engine cars to the latest electric vehicles (EVs). These processes offer unparalleled speed, consistency, and reliability in high-volume production environments.

Resistance Welding for Fuel Tank Construction

The manufacturing of fuel tanks, particularly for gasoline-powered vehicles, presents unique challenges. Safety and leak prevention are paramount. Resistance welding, specifically seam welding, is often employed for assembling steel fuel tanks. This process involves passing overlapping metal sheets between rotating copper alloy electrodes. A continuous electrical current creates a series of overlapping weld nuggets, resulting in a uniform, pressure-tight seam. The key advantage here is the creation of a hermetic seal critical for containing volatile fuels. The process parameters—current, pressure, and wheel speed—are meticulously controlled to ensure consistent penetration without burn-through, maintaining the tank’s integrity under various thermal and pressure cycles. This method is favored for its ability to produce robust, leak-proof joints at high speeds, a necessity in automotive production lines.

Spot Welding for Door Frames and Body-in-White Assembly

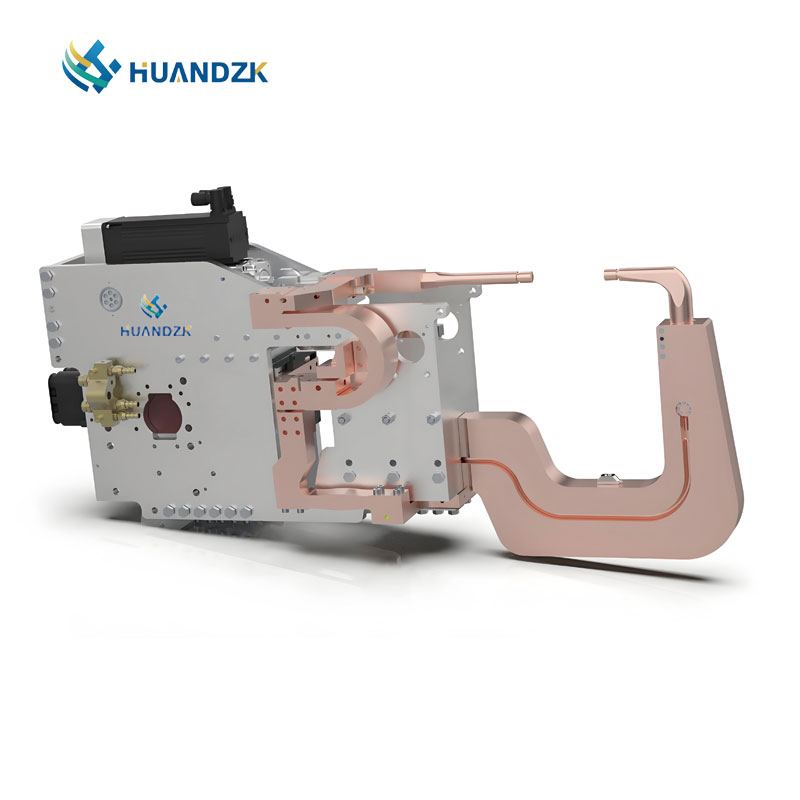

Spot welding is the predominant technology in automotive body assembly welding, often referred to as Body-in-White (BIW) construction. For structural components like door frames, pillars, and body panels, spot welding provides exceptional strength and torsional rigidity. The process uses paired copper electrodes to clamp two or more layers of sheet metal. A high, brief electrical current generates intense localized heat, melting the metal to form a fused nugget. A single vehicle body may contain several thousand such spot welds.

The evolution of automotive body assembly welding has seen increased automation, with robotic arms performing the vast majority of spot welds. This ensures repeatability, access to complex geometries, and consistent weld quality. Advanced monitoring systems now verify each weld's quality in real-time by analyzing dynamic resistance or electrode displacement, ensuring every joint meets stringent crashworthiness standards. The result is a monocoque structure that is both lightweight and exceptionally strong, forming the safe occupant cage of modern vehicles.

The Critical Role of Welding in Electric Vehicle Battery Manufacturing

The shift to electromobility has elevated welding technology to an even more critical role. EV battery spot welding and battery tab welding are specialized processes that directly impact the performance, safety, and longevity of the battery pack.

EV battery spot welding primarily refers to the assembly of the battery module casing and internal structural components. Similar to BIW applications, it creates strong mechanical joints for the module housing, busbar supports, and cooling plates. Precision is key to maintaining dimensional accuracy and ensuring proper integration of thermal management systems.

However, the most delicate and technically demanding process is battery tab welding. This involves creating electrical connections between individual lithium-ion cells (cylindrical, prismatic, or pouch) and the module's busbars. The tabs, typically made of aluminum (anode) or copper/ nickel-plated steel (cathode), are thin and highly conductive. Joining them requires a process that creates a low-resistance electrical connection without generating excessive heat that could damage the sensitive cell internals.

Ultrasonic welding and laser welding are often used alongside specialized resistance welding techniques for this purpose. When resistance welding is applied, it is a highly refined micro-welding process. Extremely precise control of current, force, and time is essential to form a nugget that ensures minimal electrical resistance and maximum mechanical strength, without causing internal short circuits or metallic spatter that could compromise safety. The consistency and quality of every single battery tab weld are non-negotiable, as a single faulty connection can lead to module failure, reduced range, or thermal runaway.

Conclusion: The Convergence of Reliability and Innovation

From the sealed seams of a fuel tank to the robust door frames, and from the vast number of welds in the automotive body assembly to the microscale precision of EV battery spot welding and battery tab welding, these processes underscore the automotive industry's dependence on reliable, high-speed joining. As vehicle designs evolve, particularly with the rise of multi-material bodies and advanced battery systems, welding technologies continue to adapt. Innovations in adaptive control, electrode design, and hybrid processes (combining resistance and laser welding, for instance) are paving the way for the next generation of safe, efficient, and durable vehicles. The relentless focus on weld quality remains a constant, forming the literal and figurative backbone of automotive manufacturing.